At a time when countries around the world are paying more and more attention to resource reuse, the upgrading and innovation of new recycling technologies is particularly important. Many times, a breakthrough in a new technology link can not only reduce the waste of more resources, but also better balance our living environment. Next, we will introduce you to an upgraded and innovative technical recycling solution – jelly cable recycling machine. What kind of machine is this? What are its features and workflow? What can we do with it? Please follow this article to know about jelly filled cable recycling machine.

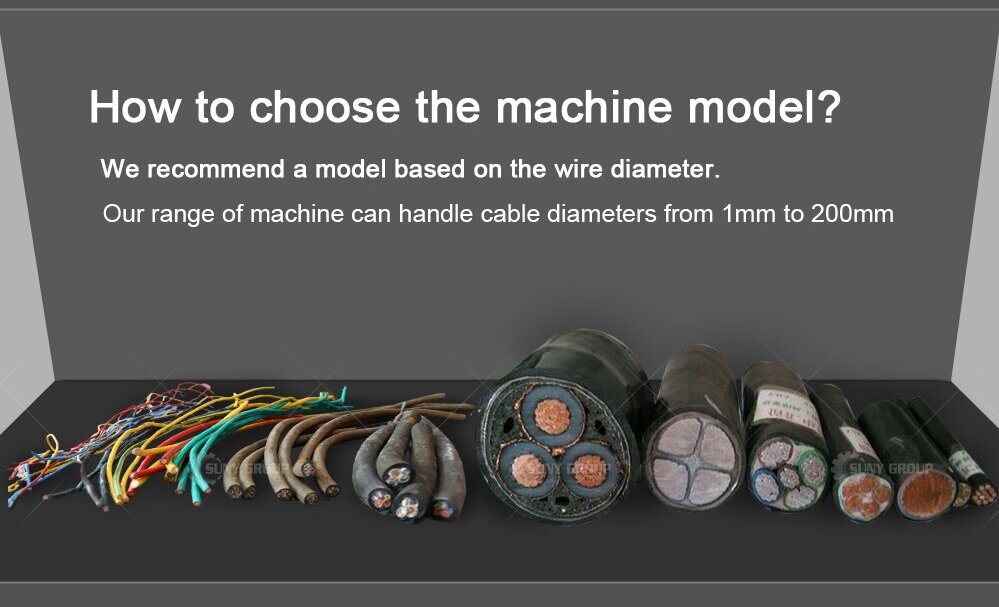

First we need to know what is jelly filled cable? Jelly-filled cable, also known as jelly-filled telephone cable or jelly-filled communication cable, is a telecommunications cable that contains a gel-like substance (usually petroleum jelly or a similar compound) within its core. This gel is used as a waterproof or moisture-proof material to provide protection for cables against the ingress of water or moisture penetration. Jelly-filled cable is typically used in outdoor and underground installations where exposure to moisture, water or harsh environmental conditions is a consideration. The gel within the cable core helps prevent water from seeping into the cable, but it also makes recycling jelly-filled cables exponentially more difficult.

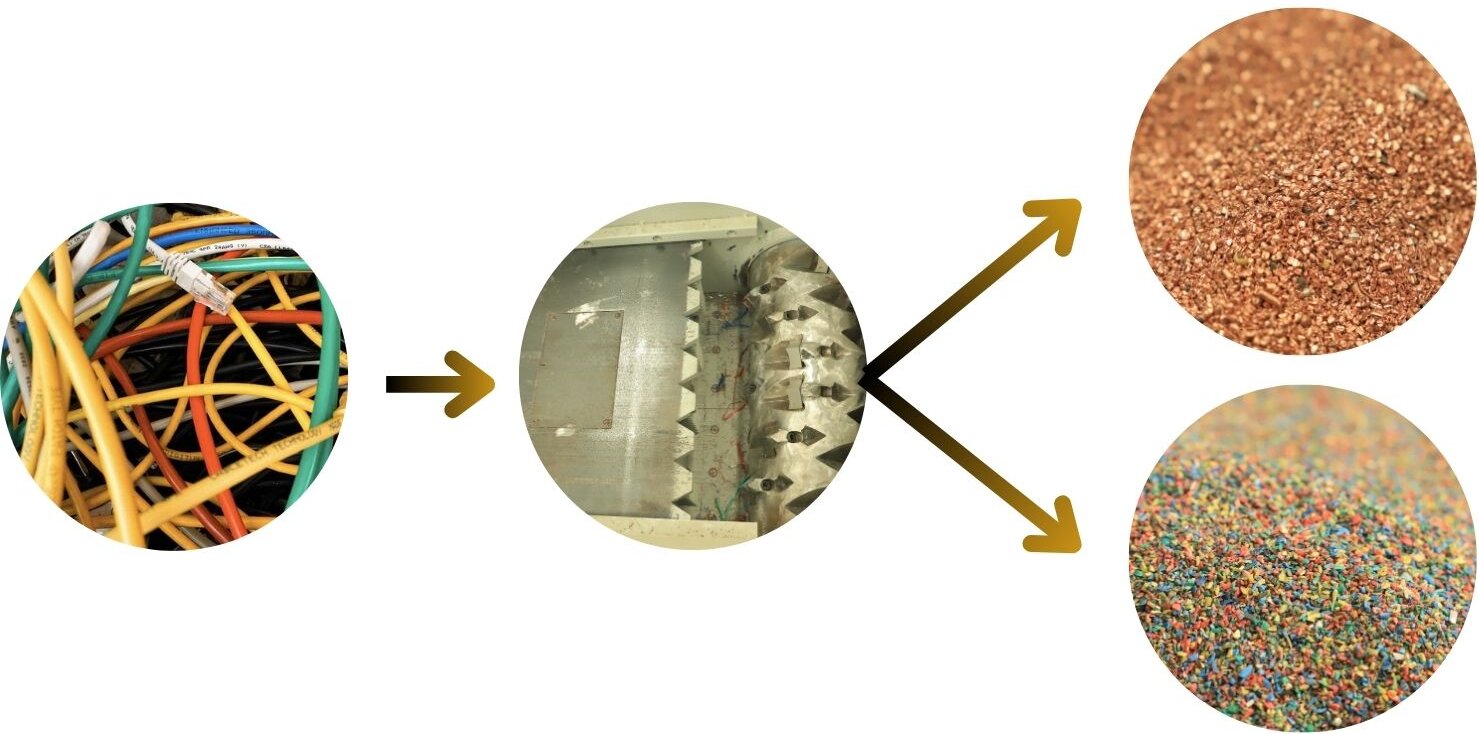

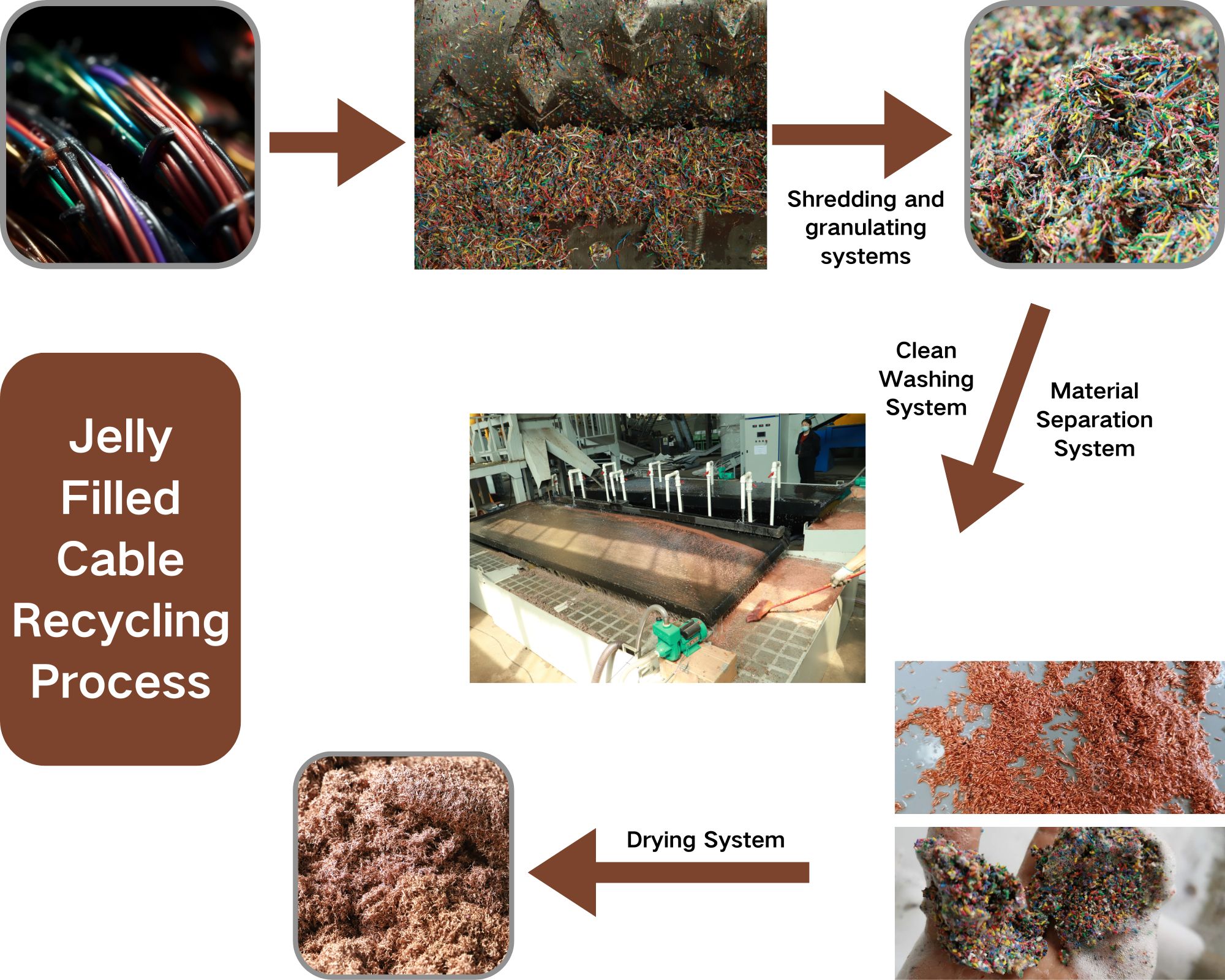

Next we can understand what a jelly-filled cable recycling machine is. The workflow of the jelly-filled cable recycling machine is divided into the following steps:

Shredding and granulating systems: Use specialized equipment such as choppers or granulators to chop the sorted jelly-filled cables into smaller pieces or granules. This process breaks down the cables into smaller components, making them easier to process further.

Material Separation System: After shredding, the shredded material undergoes a separation process that separates different materials, such as metals (usually copper), from non-metallic materials, such as insulation and gels. This may involve techniques such as magnetic separation, density separation or air separation.

Clean Washing and Drying System: Separated materials can undergo a cleaning and washing process to remove any remaining contaminants or impurities. After cleaning, the material can be dried to remove any moisture content before further processing. This helps improve the quality of recycled materials and ensures they meet recycling standards, and high-purity copper pellets can be sold at higher prices.

Currently, the jelly-filled cable recycling industry is experiencing rapid development. Especially with the government’s support and policy support for the environmental protection industry, the jelly-filled cable recycling industry will usher in a broader space for development. Growing demand for recycling, resource conservation, technological advancement, circular economy initiatives, market growth in developing regions, overall, when you join the jelly-filled cable recycling industry, you will get high financial returns. If you are having issues recycling jelly filled copper cable, please contact us for a solution.