Cable Stripping Machine

- Home

- Cable Stripping Machine

- 1-60mm Cable Stripping Machine

| Parameter | Value |

|---|---|

| Feed Diameter | 10mm – 70mm |

| Voltage | 220v |

| Power | 2.2kw |

| Weight | 88kg |

| Size | 62cm x 53cm x 85cm |

| Capacity | 1-1000kg |

1-60mm Cable Stripping MachineProduct Code : ZY-60

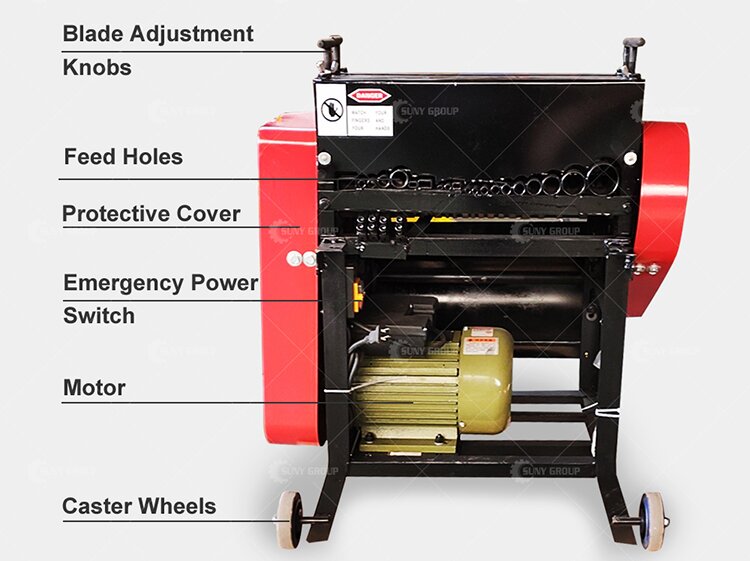

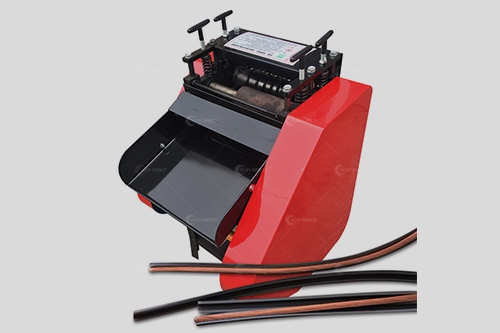

Designed specifically for cables with a diameter of 1-60mm, our stripping machines stand out for their excellent performance and reliability. Whether in industrial production lines or on-site operations, its fast stripping and high efficiency will greatly improve your work efficiency, saving you time and costs. The newly launched multifunctional wire stripping machine is specially designed to handle wires with diameters of 1-60mm. Whether operating in manual or electric mode, this machine easily strips the outer sheath and inner conductor of discarded cables. Its dual operating modes provide easy manual control and efficient automated operation through the intelligent wire stripping function in electric mode.

Contact WhatsApp Online

Try it now and upgrade your wire stripping experience!

Product Highlights:

- Simple operation and safe use

- Less investment and greater returns

- A plurality of feed holes can be selected

- Quality goods

- Patented Product

- Environmental protection

- High Recovery Rate

- The blade adjusting rod isconvenient to adjust the bladedistance according to the wirediameter

- Double stripping path with doubleknife, made the separationconplete,Scroll design at theoutlet avoide the wire damage.

- There are round holes and squareholes of different sizes, which canstrip wires with multiple centerdiameters

- The blade adjusting rod isconvenient to adjust the bladedistance according to the wirediameter

After-sales Service:

- Have an experienced overseas installation and commissioning technical team.

- Detailed operation manual and powerful online technical support.

- Provide buyers of finished product materials so that you don’t have to worry about how to sell finished products.

- We can guarantee lifetime supply of equipment accessories.

In terms of working and using this machine, there are mainly the following points worth noting:

- ① When the machine is working, special attention should be paid to the safety of both hands. When processing sheath lines and cross-head operations, the operator must concentrate and a safety cover must be installed in the middle.

- ② When processing sheathed wires and various cables, the pressure should not be too tight, and the operation should not be overloaded to avoid affecting the service life of each part.

- ③ If the material feeding cannot be transmitted, check whether the belt is loose, whether the pressure is too tight, or whether the position of the knife is in the wrong direction.

- ④ If this machine works under heavy load for a long time, the oil reserve of the transmission should be checked every quarter, and the four teeth of the transmission shaft should be lubricated with butter every shift.

- ⑤ The four Z208 bearings of the upper and lower spindles should be checked regularly to see if the bearings and shafts are running smoothly and whether the bearings are damaged. If this occurs, they should be repaired in time. Otherwise, if used continuously, the shaft will easily break.

- ⑥ When the upper shaft needs to be lifted for work, the heights of both sides should be relatively parallel.

- ⑦ The four lifting screws of the transmission and the four lifting screws of the motor should be adjusted regularly one by one to check whether there is any looseness. If so, the chain and V-belt should be adjusted and tightened in time. When adjusting, the transmission or motor must be relatively parallel and not too tilted.

Machine Model

Our Customer cases

Company News

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry