Some time ago, a Korean customer visited our environmental protection and recycling equipment factory for an in-depth visit. During this visit, the customer showed great interest in our Copper Wire Granulator Recycling Machine and other new energy equipment (such as Lithium Battery Recycling and Solar Panel Recycling Equipments), and especially paid great attention to the Waste Cable Recycling Machine, which was considered as the necessary choice for them to carry out new projects in the future.

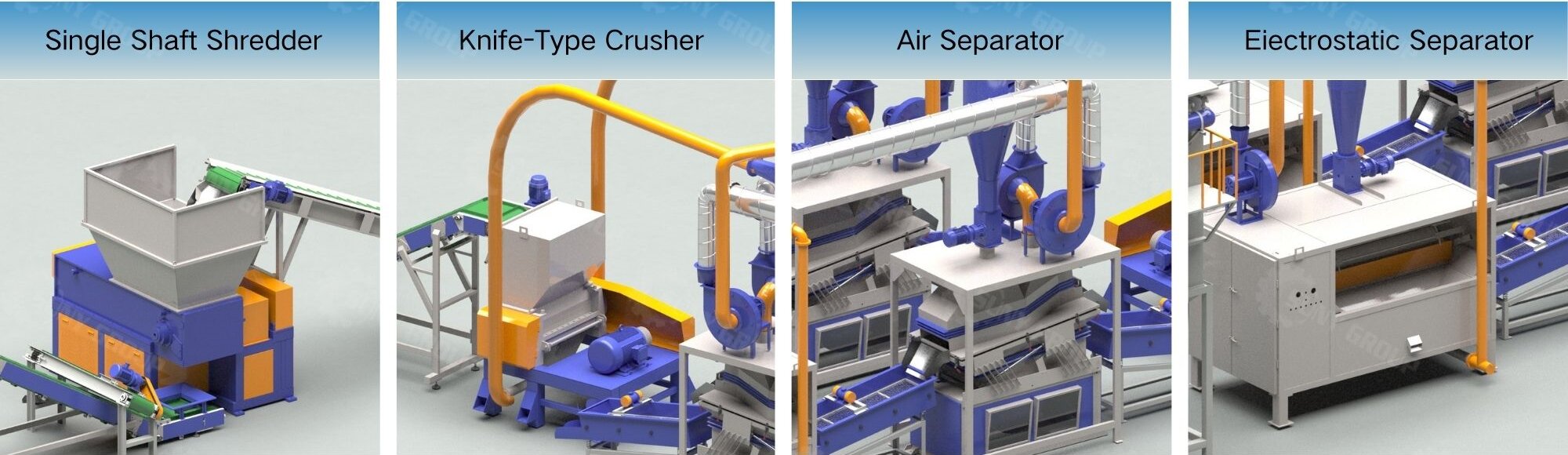

During the visit, we showed customers the overall workflow of the waste cable recycling machine in detail. Customers made detailed inquiries about every aspect of the equipment, especially focusing on how to separate the copper and plastic in the waste cables through advanced sorting technology, to ensure that the purity of copper recycling can reach the end of the industrial standard, and to get the copper particles with purity of up to 99% or more. Our technical team patiently explained the efficient separation principle of the equipment and showed how to realize high-purity copper recovery and high-quality plastic reuse through precise crushing and screening processes.

1000kg/hr Waste Cable Recycling Machine

In terms of the performance of the whole machine, we showed our customers the high-quality materials and advanced technologies used in the equipment, especially in the selection of blades and motors, which ensures the stability and durability of the equipment in long-term operation In addition to the waste cable recycling equipment, our customers also showed interest in our other new energy recycling equipment, especially lithium battery and solar panel recycling equipment. We showed them how to recover valuable metals from lithium batteries and silicon materials from solar panels through advanced technology, which further broadened their knowledge of our equipment technology.

Through this visit and exchange, Korean customers have a more in-depth understanding of the technical advantages and market potential of our waste cable recycling machine, and the two sides’ intention to cooperate in the field of environmental protection and recycling has been further strengthened. If you are interested in learning more information or wish to visit the actual operation process of the equipment, please feel free to contact us. We will provide you with the most professional technical support and services to help your business achieve greater success in the waste cable recycling industry.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com