New Center

The choice of scrap cable recyclers, efficient cable crushing and separating system

November 14, 2024Scrap cables are ubiquitous in life, but when they are no longer in use, if they are not recycled and disposed of in time, they will cause serious pollution to the environment. How to effectively recycle used cables, reduce environmental pollution, and improve the reuse rate of resources has become an urgent problem in the industry. To this end, SUNY GROUP has launched the “1+2” waste cable recycling line, which adopts an innovative design that not only improves production capacity but also reaches a new height in terms of recycling efficiency and quality.

This recycling line is an integrated equipment system with a powerful processing capacity for all types of waste cables (0.3mm-35mm). Whether it is mixed cables, communication cables, or household wires, it can handle them all efficiently and is particularly suitable for investment by large recycling companies, waste treatment plants as well as environmental entrepreneurs.

800 – 1000 kg/h cable recycling system

In terms of size parameters, the cable recycling system weighs 8,200 kg, measures 12 x 4.1 x 4.5 meters, and has a power of 95 kW. The design of the cable recycling line is a highlight, with one shredding system paired with two sorting systems. This well-built design effectively increases the machine’s production capacity and recovery rate and has been rigorously tested to have a stable production capacity of 800 to 1,000 kilograms per hour, which is sufficient to cope with all kinds of waste wire processing needs. With this system, scrap cables can be efficiently crushed and sorted to maximize the recovery of valuable metal and plastic materials, reducing resource wastage and minimizing the negative impact on the environment.

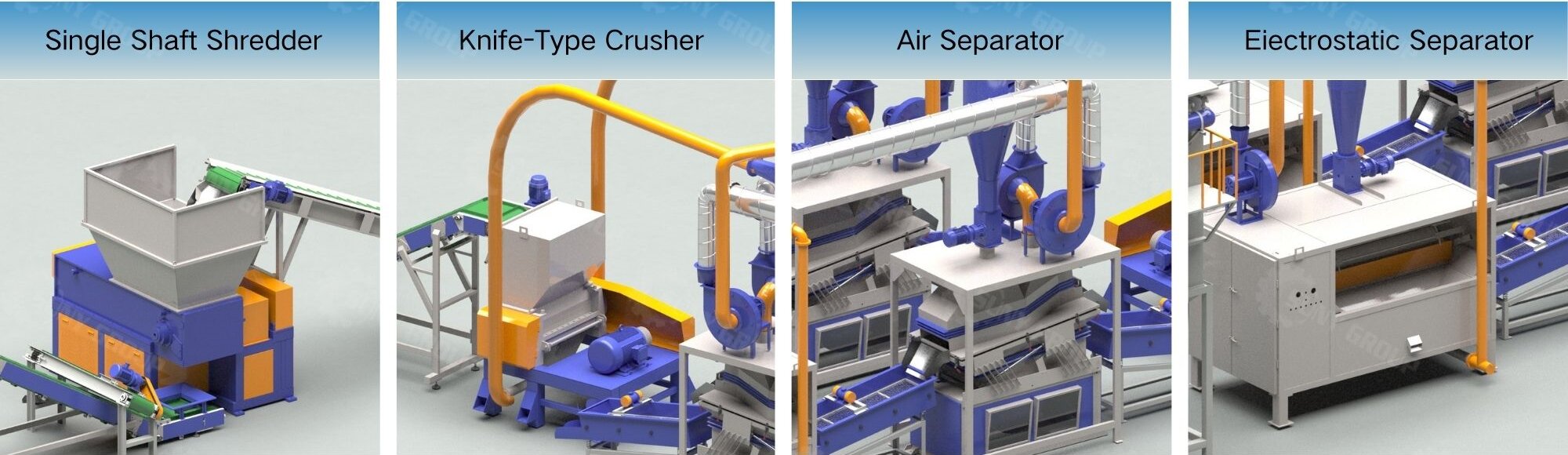

The system is equipped with a state-of-the-art single-shaft shredder, knife crusher, two sets of air separators, and two sets of electrostatic separators. This sophisticated equipment works in tandem to ensure that the cable recycling process is efficient and accurate. The single-shaft shredder provides initial strong crushing of the cables, laying the foundation for subsequent processing; the knife crusher further refines the materials to make them easier to sort; the air separator utilizes the principle of airflow to initially separate materials of different weights and materials; and the electrostatic separator, by electrostatic action, accurately separates metallic and non-metallic materials, thus realizing high-purity recycling.

With the development of the waste cable recycling industry, the market demand for equipment is growing, and companies are looking for more efficient and environmentally friendly solutions. This 800 – 1000 kg/h cable recycling system is sufficient to meet your recycling requirements. Our professional team will provide you with detailed technical support and equipment demonstrations to help you better understand how the system works and how it can be used. If you would like to learn more about this system or see it in action, simply contact us today.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry