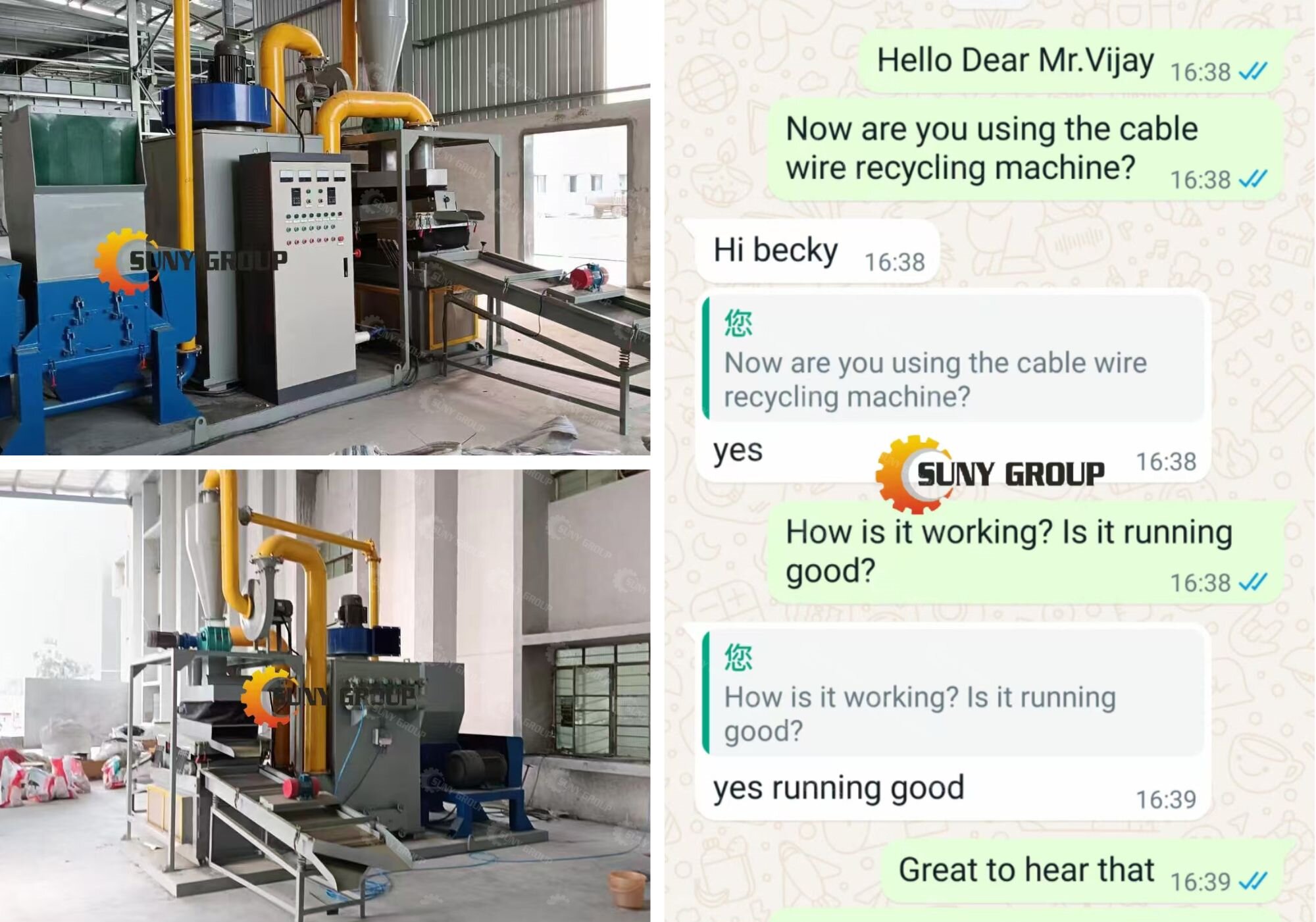

Recently, cable recycling equipment to be sent to the Netherlands has completed the feeding test run in our factory. This equipment is customized according to the specific needs of the Dutch customer, and after several months of design, production, and assembly, it has finally come to the key acceptance link. To ensure the stability and efficiency of the equipment before delivery, the customer sent a technical team consisting of technical supervisors and engineers to our plant for on-site acceptance and performance testing and participated in the whole feeding trial process.

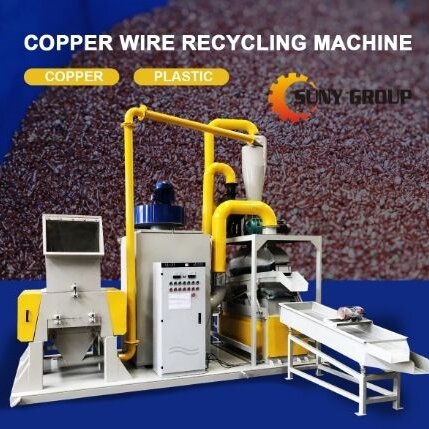

300-400kg/hr cable recycling machine for Dutch customer

On the day of acceptance, our factory arranged a detailed demonstration of feeding and testing for the customer’s team. After the equipment was started up, the waste cables were crushed, separated, and processed in turn, and the recovered metal (copper) and other materials (plastics) were separated efficiently, which fully demonstrated the precise design and manufacturing process of the equipment, and the overall performance was in line with the customer team’s expectations. The on-site technicians continued to record the data and exchanged with us the indicators and feedback during the testing process.

The equipment is equipped with an advanced automated control system with an easy-to-understand interface and multi-language display, ensuring that the customer’s operation team can use it locally with ease. We have also fine-tuned the machine to better suit the customer’s site and specific needs.

The cable recycling machine will soon be shipped to the Netherlands and put into production, and we are confident that it will play an important role in the local waste cable recycling program, helping the customer to achieve higher economic efficiency and environmental protection goals.If you have any questions or need further information, please feel free to contact us. Our contact information is as follows:

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com