A cable copper wire recycling machine is designed to process various waste cables and separate copper, aluminum, and other valuable metals from insulation materials. For different production needs, users can choose compact systems for limited space, reinforced models with higher output, or large-scale lines equipped with heavy-duty crushers and electrostatic separation units. The final selection depends on scrap volume, available space, and the desired copper recovery rate.

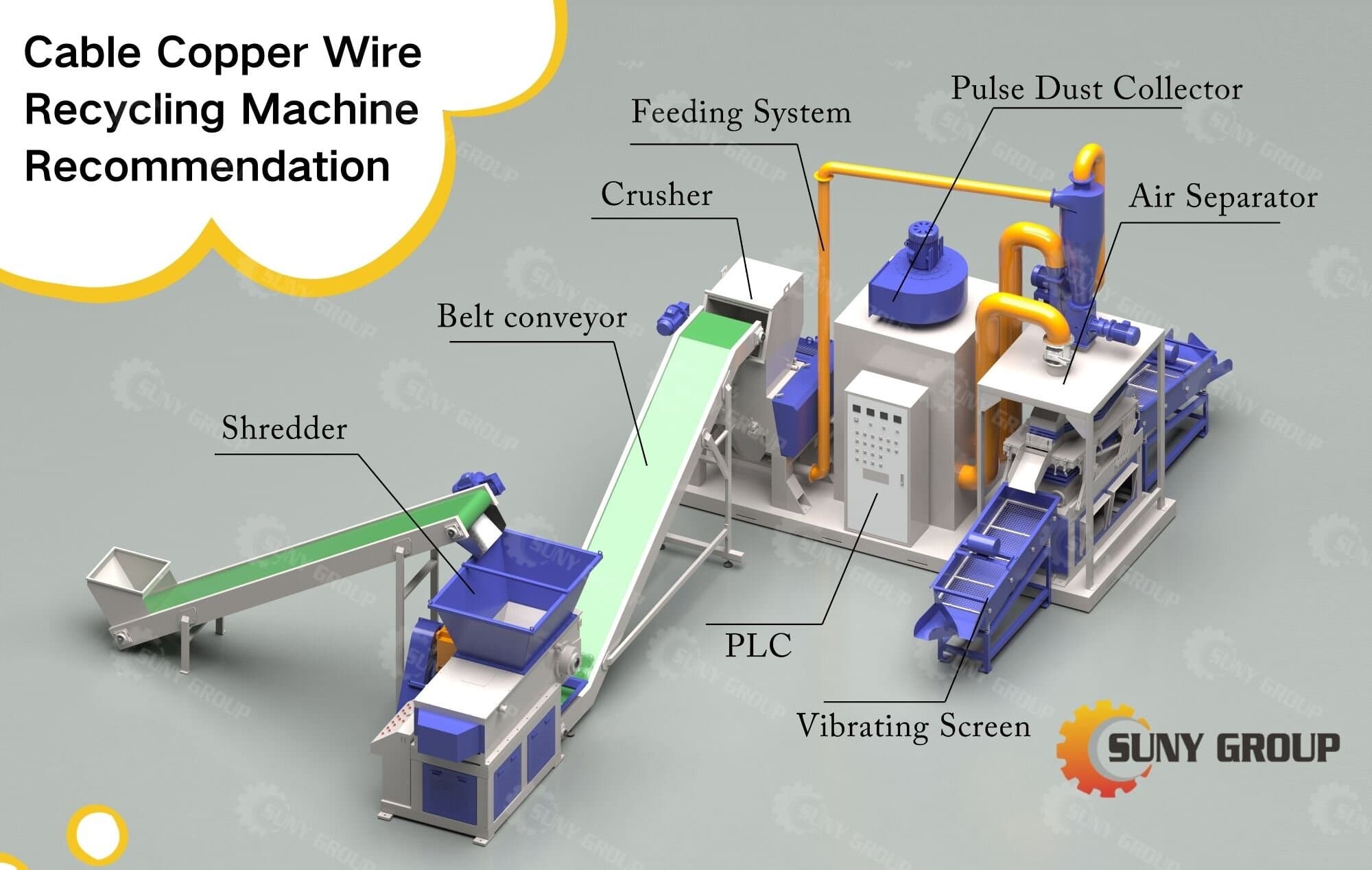

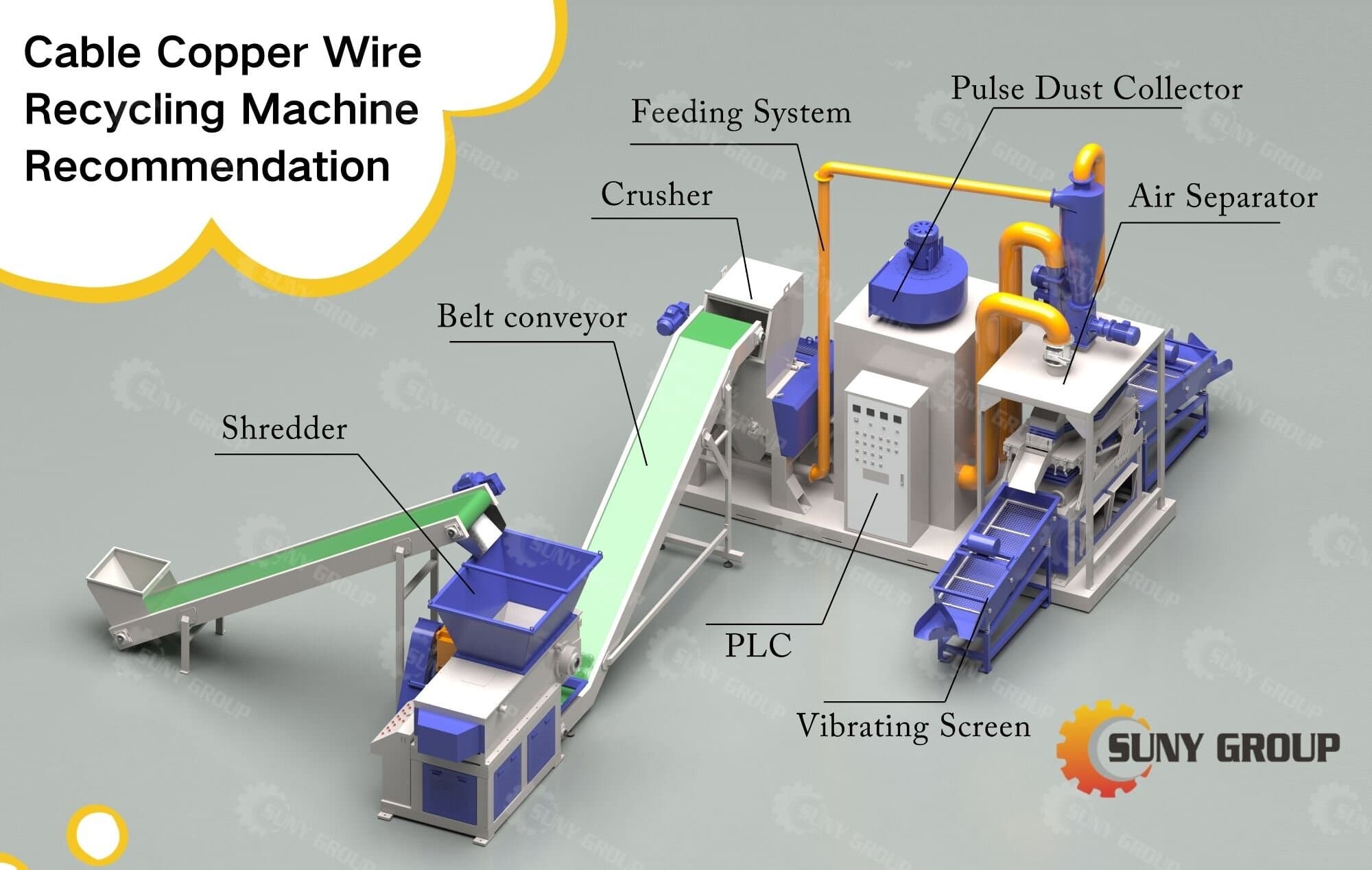

Our enhanced cable recycling line adopts a highly efficient process that includes a single-shaft shredder, belt conveyor, crusher, feeding system, pulse dust collector, air separator, vibrating screen, and PLC intelligent control. This upgraded configuration increases capacity, improves separation accuracy, and maintains a clean and stable working environment. With a reinforced layout and optimized airflow system, copper recovery can reach up to 99.9%, achieving 100% purity comparable to European machines.

Cable Copper Wire Recycling Machine

When choosing a recycling machine, the key considerations include the machine’s processing capacity, the types of cables handled, durability of the structure, and operational convenience. High-quality materials and robust assemblies ensure long service life—many users have operated our equipment for over ten years with minimal maintenance. Ease of use is equally important: intuitive PLC controls, simplified maintenance points, and automated detection functions reduce labor intensity and prevent raw-material waste. For users with mixed cable types, our machines can process almost all common copper and aluminum cables without repeated adjustments.

Investing in a high-efficiency granulator provides significant economic and environmental benefits. The mechanical crushing and separation process converts waste cables into high-value recycled copper while operating with pulse dust-removal for pollution-free production. Recycling helps reduce raw-material costs, supports environmental sustainability, and increases profitability through the sale or reuse of recovered metals.

We are a professional manufacturer of recycling machinery with strong technical expertise and complete service support. Our team provides tailored solutions based on your cable type, capacity requirements, and factory layout. For more details or to arrange an on-site or virtual factory visit, please contact our sales team anytime.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com