ACSR Cutting Recycling Machine, an efficient cutting line for all sizes of ACSR. Suny Group’s ACSR system cleanly separates ferrous and non-ferrous materials. The system is capable of handling large volumes of ACSR cables or similar materials. How can you achieve recycling savings with the ACSR Cutting Recycling Machine?

ACSR (aluminum steel core stranded wire) recycling machines

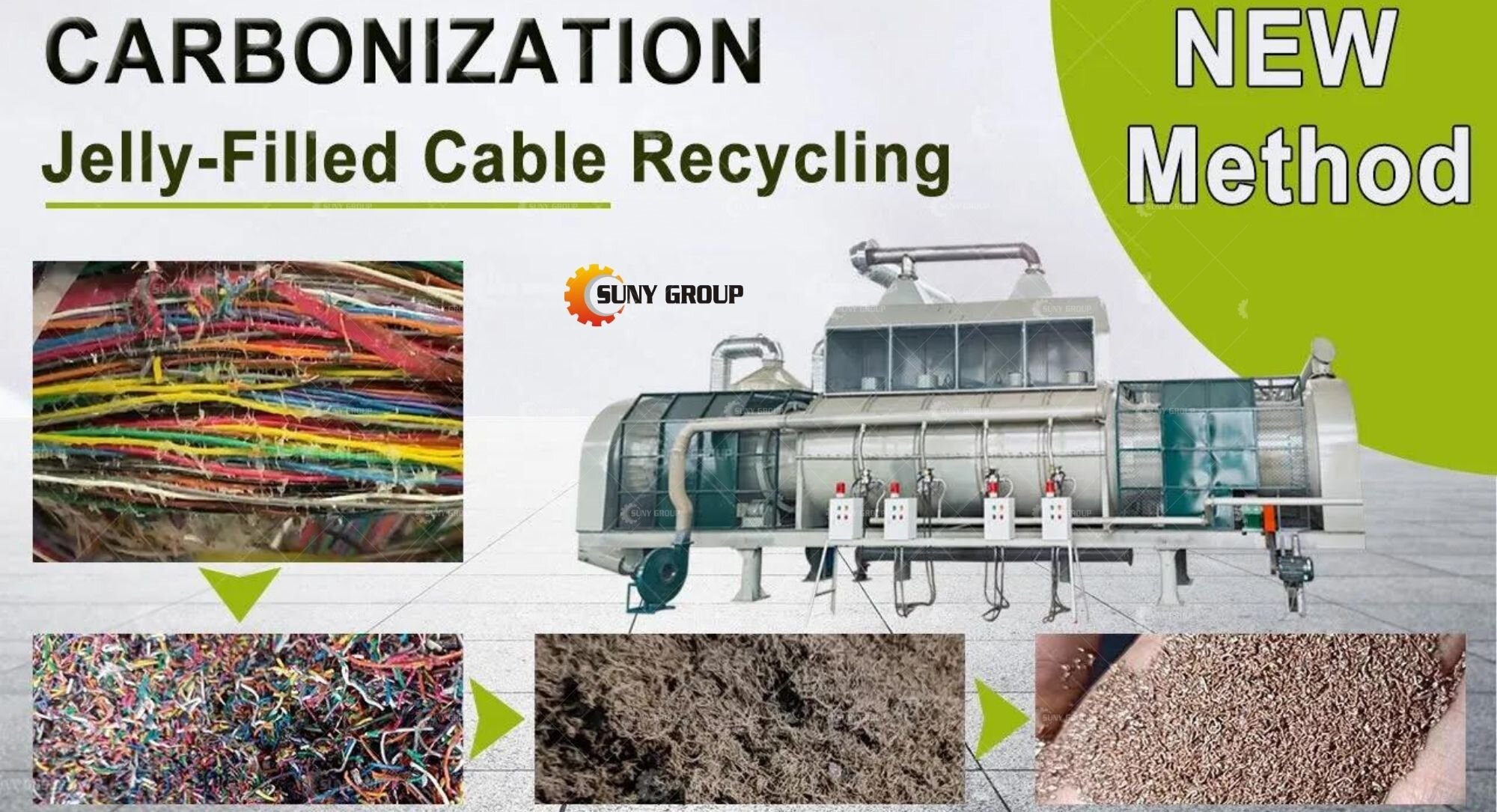

Featuring a rugged design and seamlessly integrated features, the Suny Group ACSR recycling system optimizes cable separation with innovative technology. This allows for maximum scrap metal recovery, simplified system maintenance, and durable construction. Equipped with a PLC control cabinet, it is durable and can withstand harsh environments, simple and minimal maintenance. There is also a magnetic separation system to capture steel chips from missed scrap metal as it passes through.

Suny Group’s new in-line separation system uses high-powered rare earth magnets to separate all ferrous materials from mixed materials. Unlike typical magnetic cross-belt systems that run perpendicular to the conveyor and have a high tendency to flip and drag material over the conveyor and conveyor walls, the in-line system gently removes ferrous metal from the front of the material stuck between the conveyor and the conveyor as the material never drags from the sides of the conveyor. Depending on the space requirements, Suny Group’s in-line separation system can be combined with a high-strength rare earth magnet secondary pass system to achieve a product purity of 99.99%. This ensures that the end product contains virtually no ferrous material that could degrade the quality and prevent it from being sold at the best market value.

The product range offered by Suny Group is known for its high performance, excellent working efficiency, low maintenance and energy efficiency. The machines offered by us are manufactured as per the set norms and regulations of this industry and are suitable for recycling electrical wires. Keeping in mind the different requirements of our customers, we offer ACSR Recycling Machines with different technical specifications at affordable prices. Continuous innovation, coupled with a keen understanding of customer needs, has made us the most renowned manufacturer and supplier of ACSR (aluminum steel core stranded wire) recycling machines.