Today’s cable recycling industry is paying more and more attention to improving the efficiency of cable recycling, because this is one of the most effective ways to reduce production costs, is an important guarantee for the sustainable development of enterprises, and is also the eternal pursuit of enterprises. In order to meet the market demand of the cable recycling market, reduce production costs, and improve recycling quality, the application of automated equipment has become increasingly important. Suny Group’s high-performance cable stripping machines are loved and welcomed by customers in the global cable recycling industry for their excellent performance and multiple advantages. Everything you want to know is here.

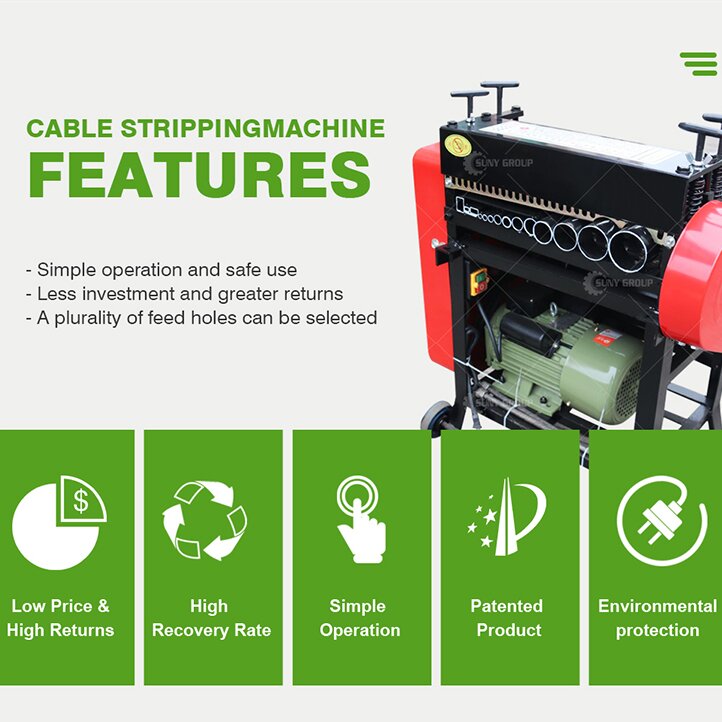

First of all, traditional manual wire stripping work is cumbersome, time-consuming, and requires a lot of labor, which not only increases production costs, but also lags behind automated mechanical equipment in recycling efficiency. The biggest advantage of high-performance cable stripping machines is efficient production. Through advanced automation technology, the one-click stripping function makes the entire wire stripping process extremely fast. Compared with the traditional manual wire stripping method, the high-performance cable stripping machine can save a lot of labor costs, improve work efficiency, and is also very safe and stable.

Secondly, compared to traditional manual stripping, high-performance cable stripping machines are highly accurate. It will use advanced sensing technology and intelligent control systems to accurately identify the specifications and materials of cables, ensuring the accuracy and consistency of each stripping operation. This not only improves product quality, but also reduces the loss rate during the production process.

In addition, the stability of high-performance cable stripping machines is also one of its outstanding advantages. After careful design and strict testing, its structure is stable and runs smoothly. It can work continuously for a long time without failure, ensuring the stable operation of the production line.

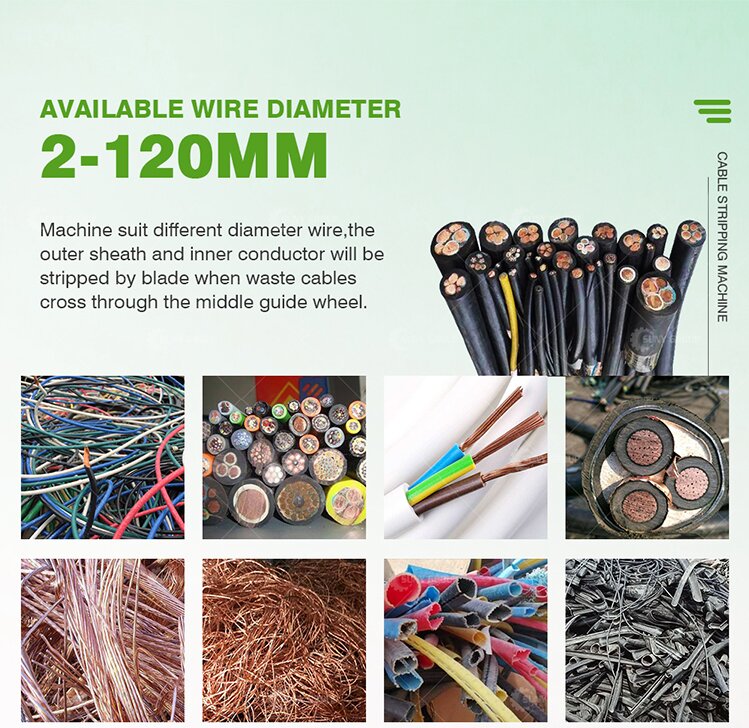

In addition, high-performance cable stripping machines are extremely adaptable. Whether facing cables of different specifications and materials, or dealing with complex working environments, it can easily handle various production needs.

Finally, the intelligent operation of high-performance cable stripping machines is also worth mentioning. The operation is simple and easy to learn, and no complicated training is required to get started. While ensuring efficient production, it also saves labor costs and training costs for enterprises, and improves the management efficiency and production efficiency of cable recycling customers.

So if you are looking for a high-performance cable stripper for cable sweat recovery, consider our product. If you have any questions about the cable stripping machine, you can contact us at any time and we will arrange professional technicians to provide you with the most effective solution. Please don’t hesitate, take action now! You can contact us by phone, email or online contact.