If you are an individual or business collecting copper wire for recycling, choosing a production tool that can be efficient and stable in the actual production process is a basic condition for the recycling business. Today we will first introduce a multifunctional small copper wire stripping machine to achieve the least investment and the greatest return. I hope it can help you start your cable recycling business.

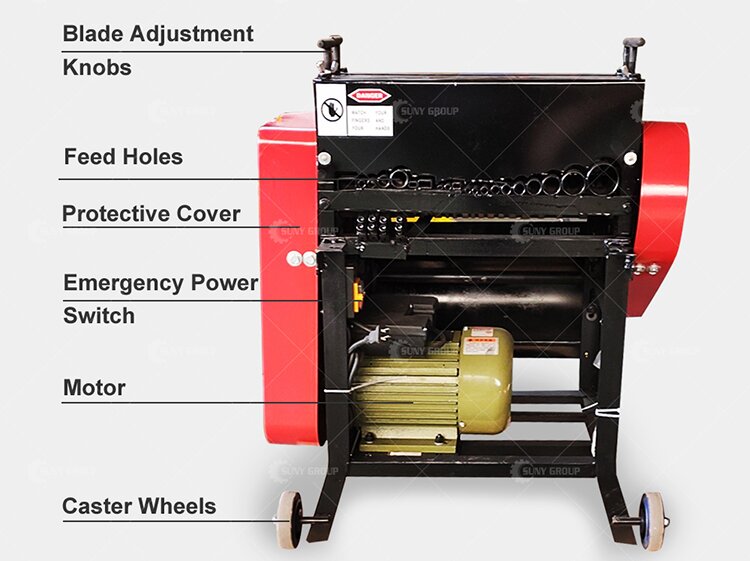

When you collect copper wire for recycling, the first thing you will notice is that you will end up with a variety of wires of different sizes. Messy cables of different wire diameters and sizes will pile up in your warehouse and recycling workshop in large quantities. There is no need to worry too much. This is a step that every cable recycler will go through. If you want to achieve the least investment and the greatest return, then you can consider Suny Group’s multifunctional small copper wire stripping machine. This small machine is perfect for electricians, contractors, handymen, small recycling yards and those who are just getting started in the field. It can handle copper wire sizes from 1 to 200 mm.

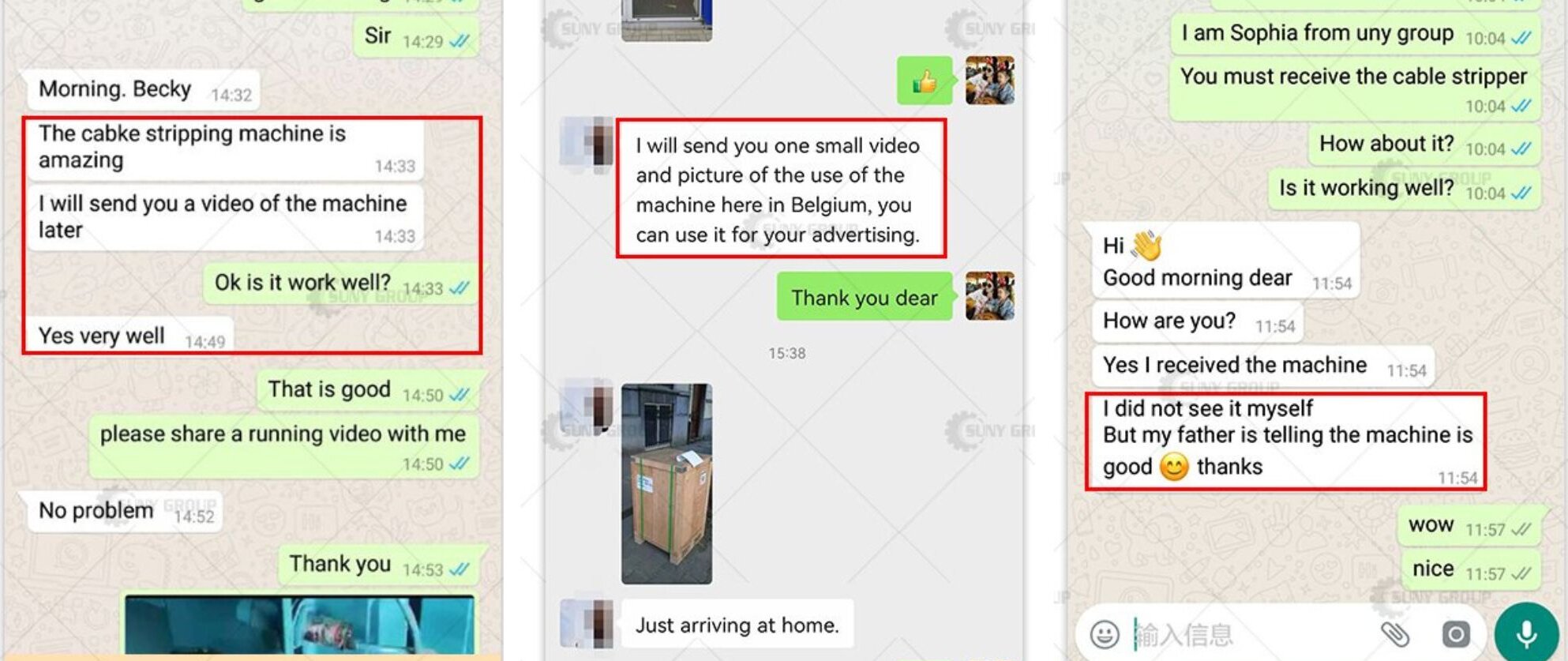

Because of its efficiency, versatility and unmatched rugged body (made of aircraft-grade aluminum alloy), and feed drive made of surgical 304 stainless steel, these features will keep this already impressive wire stripping tool in good working condition for a long time. We have also received many practical compliments from users.

It is also appreciated for its streamlined design and multi-layer stripping capabilities. As an added feature, it has a blade depth reference indicator on the top knob, which allows anyone to easily adjust the blade height when stripping copper wire. So what are you waiting for? There is a lot of money to be made in recycling scrap copper wire, and Suny Group’s versatile small copper wire stripping machine is the only one among many options that can help you achieve the minimum investment and the maximum return.