Not long ago, a group of customers from Sri Lanka were invited to visit SUNY GROUP factory, to conduct field inspections and personally experience the entire process of the company’s cable recycling and PCB recycling machine production and delivery. This visit not only allowed customers to gain an in-depth understanding of SUNY GROUP’s production strength and technical level, but also further enhanced the confidence of both parties in cooperation. When the customers arrived at SUNY GROUP factory, they were warmly welcomed by the company’s senior management and employees. The company prepared a simple and grand welcome ceremony for the customers. Afterwards, the company’s head led the customers to visit the exhibition hall and introduced the company’s development history, business scope and future development plans in detail. Through the physical display and video demonstration in the exhibition hall, customers have a preliminary understanding of SUNY GROUP’s overall strength and corporate culture.

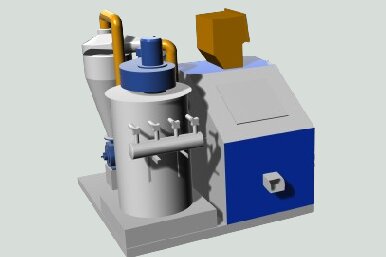

In the workshop, the machines roared, and the workers were busy and orderly operating various production equipment. The technicians explained in detail every production link, including material selection and processing, machine assembly and commissioning, quality control and testing, etc. The customer not only saw the precise production process, but also touched the equipment parts being produced in person, and deeply felt the strict requirements and superb technology of SUNY GROUP in production process. The technicians demonstrated the working principle and technical advantages of the machine to the customer through drawings, models and actual operation.

In order to ensure the quality of each equipment, SUNY GROUP has established a strict quality control system in the production process. The customer visited the quality inspection workshop and witnessed the various inspection processes of the equipment before leaving the factory. From the physical performance test of the hardware to the functional verification of the software, every link reflects SUNY GROUP’s high attention to product quality. The customer expressed high appreciation for SUNY GROUP’s rigorous quality control process and advanced testing equipment. The customer saw the equipment to be delivered, neatly arranged and well packaged. The technicians introduced the final inspection and packaging process of the equipment before leaving the factory to ensure that each equipment is not damaged during transportation. At the same time, SUNY GROUP also provides customers with detailed operation manuals and technical support to ensure that customers can smoothly install and use the equipment after it arrives.

In the future, SUNY GROUP will continue to uphold the concept of “technology is guarantee, quality is life, service is foundation, brand is goal”, constantly improve its own strength, and provide better products and services to global customers. If you are interested in our cable recycling products and services, or have any questions, please do not hesitate to contact our team immediately.