Shanghai, June 13, 2024 – The 18th SNEC International Solar Energy Industry and Photovoltaic Engineering Exhibition opened grandly yesterday. As one of the world’s largest and most influential photovoltaic events, SNEC attracts well-known companies and professional visitors from all over the world. Suny Group showcased its latest cable recycling equipment and copper wire stripping machines at the exhibition, which attracted widespread attention.

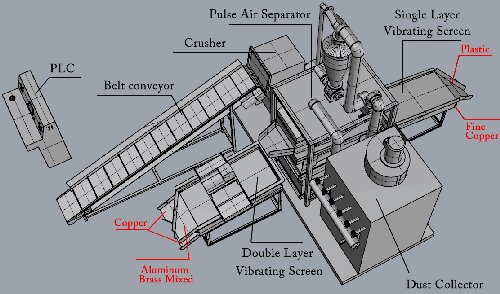

On the second day of the exhibition, Suny Group’s booth attracted a large number of visitors to stop and consult. The company’s technical experts and sales staff introduced the working principles, technical advantages and application scenarios of cable recycling equipment and copper wire stripping machines in detail, and demonstrated the operation process of the equipment on site. A customer from India said: “Suny Group’s cable recycling equipment is very efficient and can help us better recycle waste cables and save costs. The copper wire stripping machine is also very easy to operate and is very suitable for our daily work needs.” Another customer from Germany spoke highly of the environmental protection design of the equipment: “Suny Group’s equipment is very well done in terms of environmental protection, especially the design of the dust removal system, which can greatly reduce dust emissions during the production process, which is a point we attach great importance to.”

Cable recycling equipment is one of the highlights of Suny Group’s exhibition. The equipment is designed to efficiently and environmentally recycle metals and plastics from waste cables, reduce resource waste, and achieve sustainable development. At the exhibition site, Suny Group also displayed its new generation of copper wire stripping machines. The equipment is designed for processing copper wires of various specifications (1-200mm), with the characteristics of easy operation, high efficiency and durability, and is widely used in the recycling industry of wires and cables.

Our team warmly welcomes customers from all over the world to contact us. We will provide you with customized solutions to meet your needs with a professional attitude and rich experience. If you are interested in our products and services, or have any questions, please do not hesitate to contact our team immediately.