Jelly cables, widely used in communications, are known for their unique waterproof, moisture-resistant, and interference-proof properties. These cables are filled with a jelly-like compound, making them highly suitable for environments requiring durability and protection. But how can you efficiently recycle scrap jelly cables? The answer lies in this article.

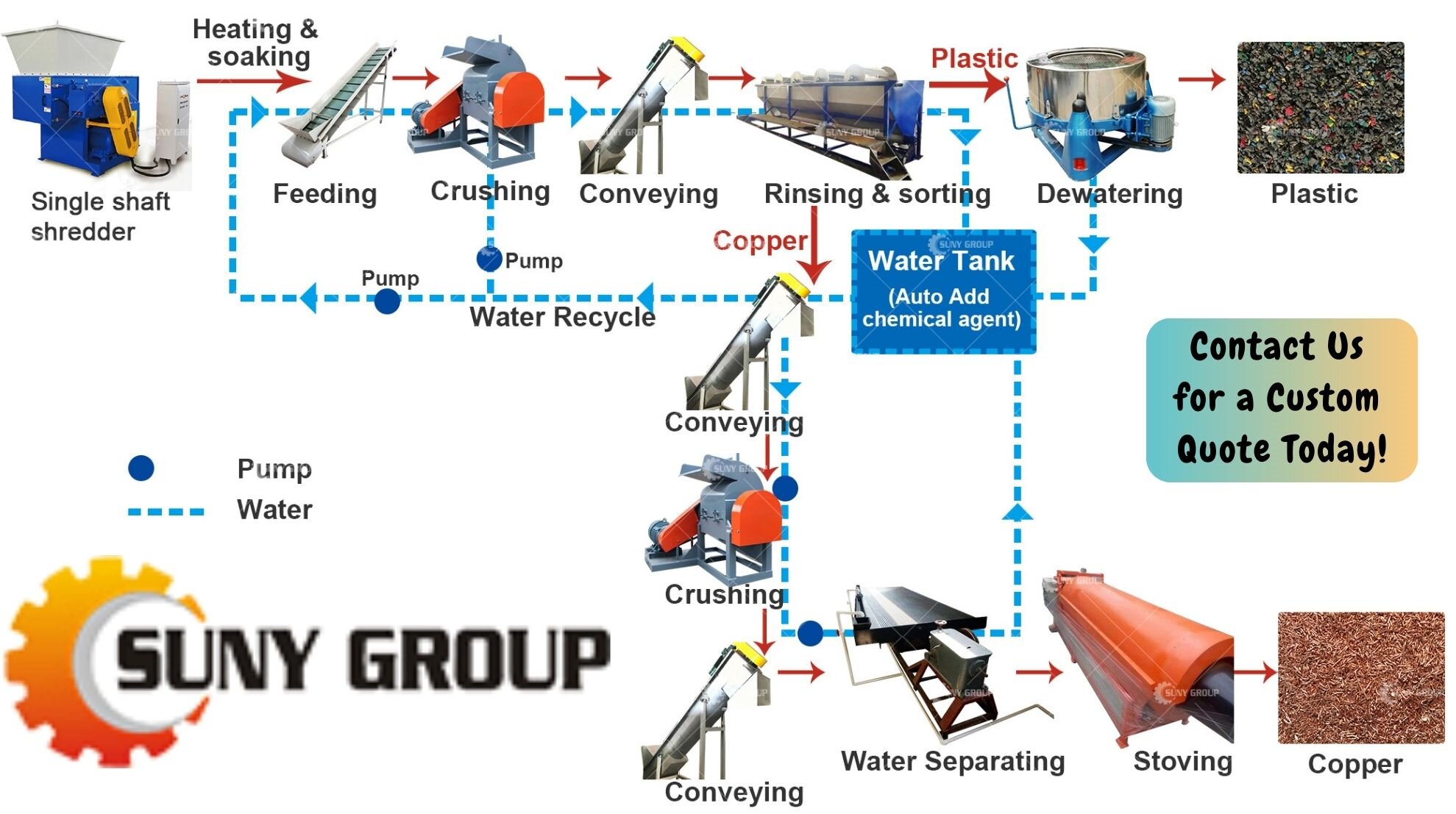

The Jelly Cable Recycling Plant offers a specialized solution for recycling this unique type of cable. The process begins with feeding the waste jelly cables into a single shaft shredder, which performs the initial crushing, breaking the material down into smaller pieces for further processing.

Next, the crushed material moves to the heating soak section, where it is softened, making the subsequent crushing more efficient. After crushing and refining, the material enters the washing and sorting stage, where water is used as the “magic hand” to precisely separate copper from plastic.

The separated plastic undergoes dewatering treatment, eventually transforming into reusable plastic products. Meanwhile, the copper enters a multi-stage treatment process, where it is crushed again, conveyed, separated from water, and dried, resulting in high-purity copper products.

One of the key features of this plant is its water recycling system. The water tank automatically adds chemicals, and water is continuously recycled through pumps, greatly reducing water waste and minimizing environmental impact.

If you’re seeking an efficient and eco-friendly solution for jelly cable recycling, the Jelly Cable Recycling Plant is the ideal choice for you. Contact us today to learn more about our machines and how they can improve your recycling process!

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com