Recently, we had the honor to receive a customer from the Netherlands who showed great interest in our company’s machinery and equipment, especially the cable recycling equipment and photovoltaic panel recycling machine. This visit not only demonstrated the high quality of our equipment and the professional strength of the factory, but also allowed us to verify our customer-first service concept again.

Before the customer’s visit, we learned in detail about his needs and itinerary for this visit. Due to visa issues, the customer was once faced with the dilemma of not being able to visit on time. In order to solve this problem, we actively communicated with the relevant departments, provided the required supporting materials, and finally helped the customer to obtain a visa smoothly and arrive at our factory as planned. When the customer arrived, we sent a professional reception team to provide him with comprehensive services. From airport pick-up to arranging accommodation, to daily itinerary arrangements, we did our best to ensure that the customer felt at home every minute of his stay with us.

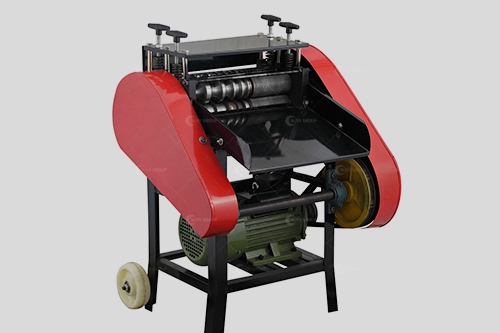

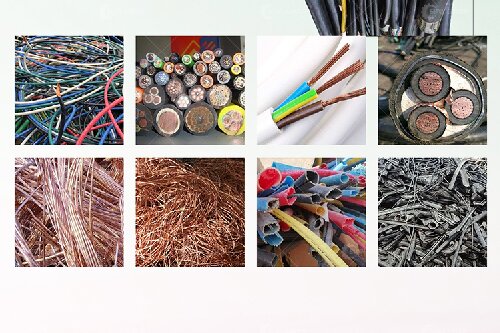

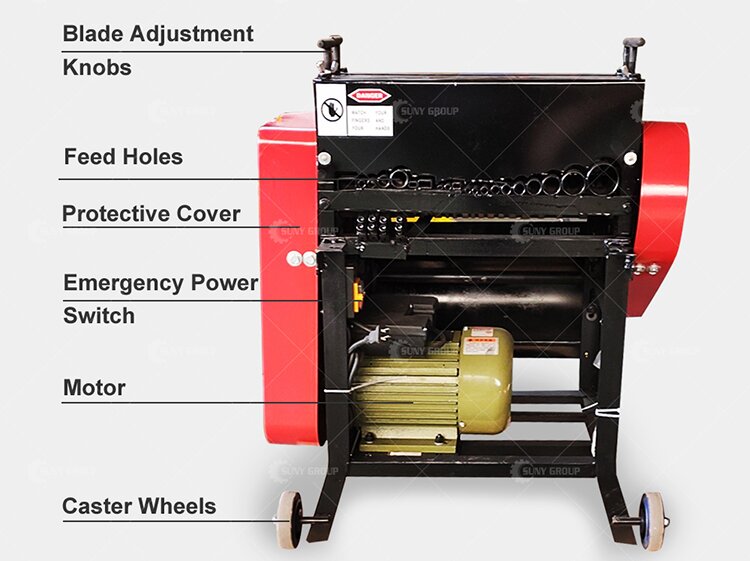

The customer was very concerned about the technical parameters and operating principles of our equipment. To this end, we arranged experienced technicians to accompany the whole process and answer customers’ questions at any time during the visit. Our technicians not only explained the working principles of each device in detail to the customer in theory, but also let the customer intuitively feel the efficient operation of the equipment through on-site demonstrations. When visiting the cable recycling equipment, the customer asked in detail about the equipment’s recycling efficiency, energy consumption and maintenance costs. Our technicians demonstrated the excellent performance and economy of the equipment to the customer through data analysis and actual operation. This theoretical and practical explanation method not only allows customers to fully understand our equipment, but also enhances their trust.

In order to let customers have a more intuitive understanding of our production strength, we arranged a comprehensive factory visit. Accompanied by us, the customer visited the production workshop of each model and each mold production machine in turn. From large to the entire production line, small to the delivery details, we showed them one by one, and introduced in detail the process flow and quality control measures of each link. During the visit, the customer showed great interest in our production environment and management system. They appreciated that our production workshop is neat and orderly, and each process has strict quality inspection. Our fully automatic production line and high-precision mold production equipment also left a deep impression on the customer. If you are interested in this business, Contact us today to learn more and take the next step towards a profitable and sustainable recycling operation.