-

Equipment:

-

Capacity:

300-500 kg/h

-

Location:

Australia

-

Application:

Copper cables, waste cables,copper wire, etc.

-

Date:

2024

In Australia, copper wire recycling equipment sites are demonstrating how efficient and environmentally friendly copper wire recycling can be. At our customer’s site, copper wire recycling equipment is converting used cables into valuable resources, a process that not only reduces waste but also saves energy and resources.

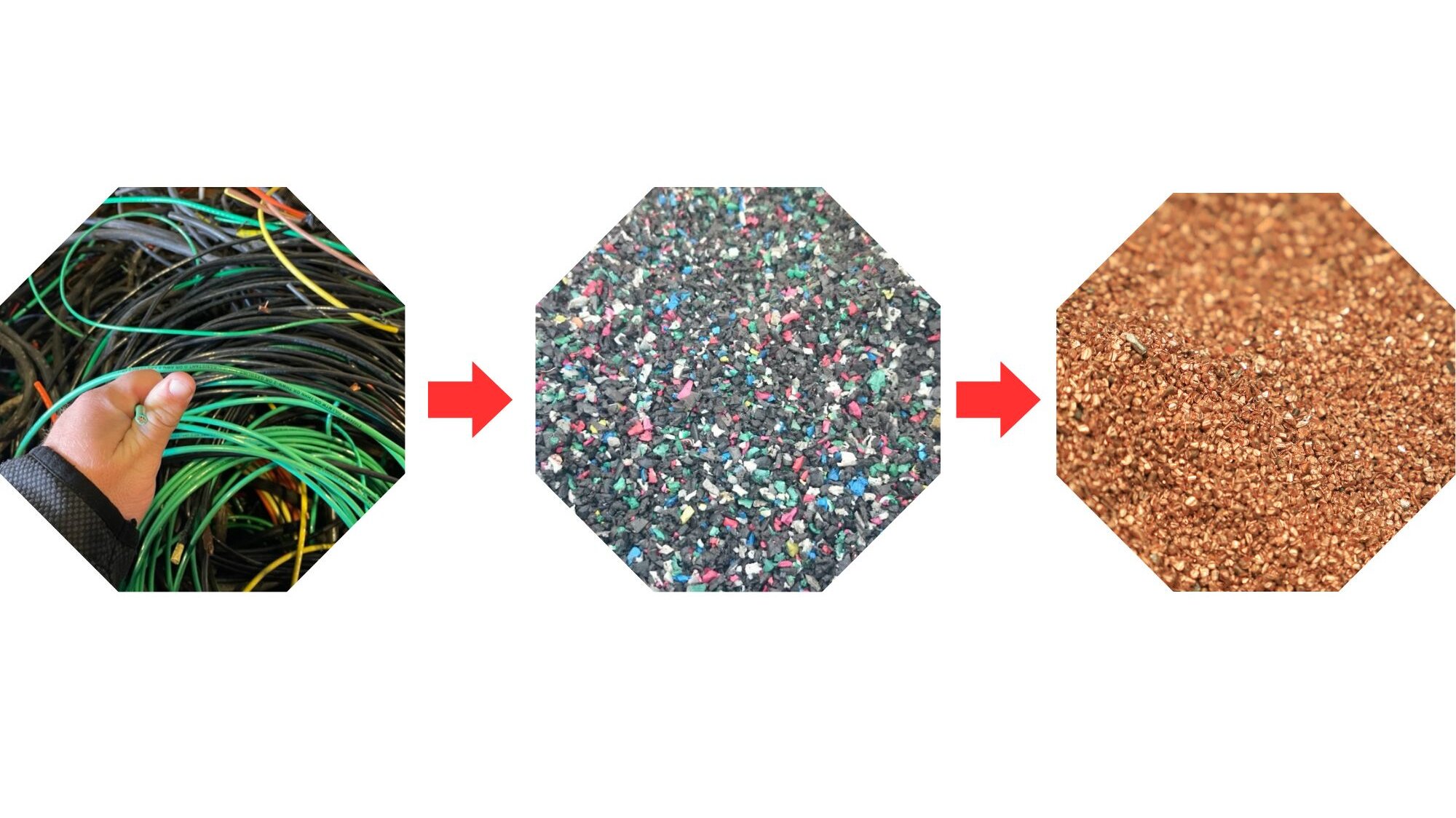

Copper wire recycling equipment workflow

First, the waste cable is fed into the crusher for initial processing, where the cable is cut into small particles. During this process, copper and plastic are initially separated but still in a mixed state. Next, the particles are fed into an airflow separator. Here, the copper and plastic are separated efficiently using the difference in gravity and airflow. The particles are suspended in the air and, depending on their weight and friction, fall onto different sides of the screen. This process ensures the separation of pure copper and plastic and optimizes recycling efficiency. To further increase the recycling efficiency, the raw material can be fed directly into the integrated plant. After initial crushing, the airflow separation system continues to separate copper and plastic using the weight and friction principle, thereby significantly increasing the purity of the separated raw material. To further increase the separation accuracy, the system is equipped with a high-voltage electrostatic separator. This advanced technology works in tandem with the pulsed airflow separator to effectively increase the purity of the copper and plastics. The system also includes a dust and fiber collection unit to ensure that waste is minimized during the recycling process.

Today, Australia’s recycling sites are a model for copper wire recycling, and you have the opportunity to replicate this success in your own business. Our team will provide you with comprehensive support and services, from equipment installation and commissioning to personnel training. Choosing our copper wire recycling equipment is choosing efficiency, environmental protection, and profitability. Act quickly and contact us to get a detailed quotation and procurement process for the machine!

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com