Starting a business is always stressful, especially when entering an unfamiliar industry. The cable recycling industry is no exception, but with the right mindset and strategy, success is not out of reach. Whether you’re striving for profitability or pushing for sustainability, these tips can help you on your way to success. Before you begin, it’s important to understand the dynamics of the industry. Research cable types, recycling processes, and environmental impacts to build a solid knowledge base. Not only will this boost your confidence, but it will also help you make informed decisions from the start. Not all cables have the same value, and high-value materials such as copper cables offer opportunities for profitability. Finding the right niche for you and focusing on optimizing the relevant processes will set you apart from the competition.

Building strong relationships is vital. Connect with suppliers, recyclers, and customers to create a supportive and collaborative network. Reliable partners can streamline business processes, foster trust, and lead to more opportunities. Choosing the right equipment is key to success. From cable stripper machines to pellet mills, quality equipment improves efficiency and profitability. Start small, but plan for future expansion. Cable recycling is not only profitable, it also provides environmental benefits. It reduces waste, conserves resources, and supports a greener future. With sustainability at its core, this sense of mission will also attract more environmentally conscious customers and partners.

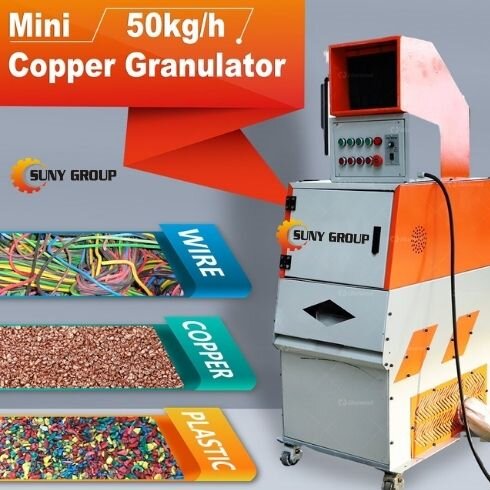

300kg/h Copper Wire Recycling Machine

Don’t wait for the perfect time, success comes from action. Start with small steps and expand gradually. The cable recycling industry is growing rapidly and now is a great time to get in and create an impact. Starting a business takes time. Start small perfect your processes, and gradually expand as you learn more about the market and the business. Steady growth is the only way to achieve long-term stability and profitability. While the process can be challenging, persistence is the key to success. Learn from failure, adapt to change, and keep moving forward. With determination, success is closer than you think. These tips apply not only to the cable recycling industry but to any entrepreneurial journey. Research, persistence, and strategic growth are the cornerstones of success. Start small, learn to deal with challenges, stay focused on your goals, and the future is sure to pay off. Take the first step, seize the opportunity, and the path to success is within reach.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com