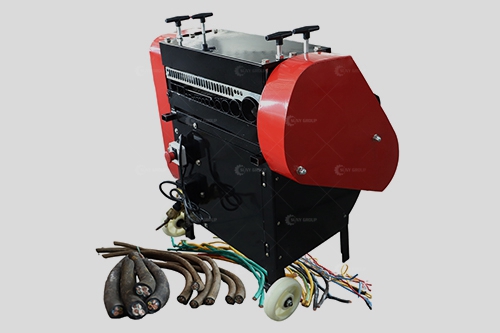

The wire stripping machine market is constantly developing. The global wire stripping machine market size will be US$547.1 million in 2022 and is expected to grow to US$901 million by 2031. One of the main drivers of this growth is the growing demand across industries for efficient, automated wire stripping processes. The growing focus on recycling and environmental sustainability has also created demand for wire stripping equipment. Recyclers are increasingly adopting automatic wire stripping machines, which offer greater accuracy and efficiency than manual methods.

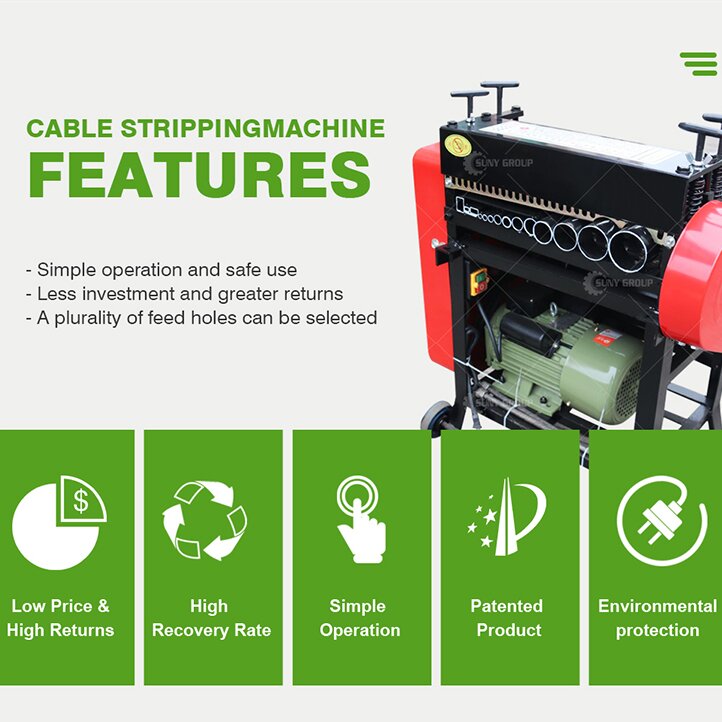

Additionally, advances in technology have led to the development of more sophisticated wire stripping machines. These machines offer greater precision, speed and efficiency, thereby reducing human error and increasing productivity. Among the world’s wire stripping machine suppliers, the wire stripping machines produced by Suny Group have won the trust and support of many customers for their high efficiency, energy saving, favorable price, stable performance and global after-sales service. Today, we will unravel the mystery behind the Suny Group automatic wire stripping machine becoming the trend of the future.

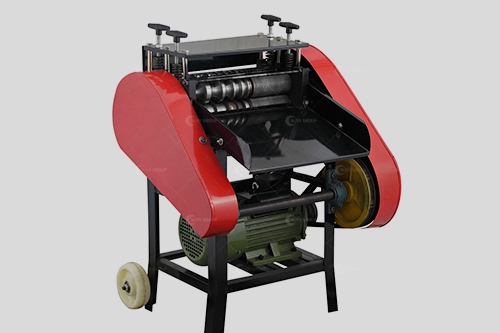

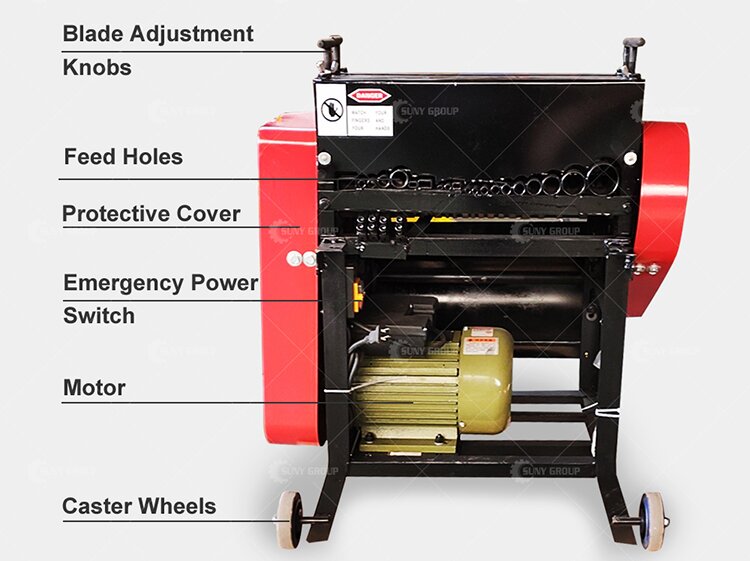

Gap control: The gap of the wire feed wheel is within reach. Easily adjusts to accommodate different cable sizes, ensuring precise wire processing.

Wire feed roller: This roller is the power source for cable transmission and wire stripping. Not only can it strip wire ends and tails, it can also handle multiple internal parts of short wires.

Outgoing roller: Responsible for cable transportation and wire tail stripping. The outgoing roller plays a vital role in seamless wire processing.

Wire feed wheel lifting: When threading, lift the wire feed wheel to make the wire routing smooth. Lower it to hold the cable in place during operation.

Knife holder assembly: This assembly cuts cables, strips heads and tails. Make sure the upper and lower blades are open to the maximum extent to allow easy passage of cables during machine downtime.

Pressure control: finely adjust the wire feed wheel pressure according to the cable insulation strength. If stripping is challenging, increase it; if stripping is easier, reduce it.

Exit wheel gap control: Precisely control the exit wheel gap according to the cable thickness. Adjust the upper and lower screws to accommodate various cable sizes.

Exit wheel pressure control: Adjust the outlet wheel pressure according to the strength of the cable sheath. This value should be increased for stiffer wires and reduced for easier stripping.

Outgoing cable roller lifting: Lift the outgoing cable roller to facilitate cable removal during shutdown. Lower it to work, holding the cable in place.

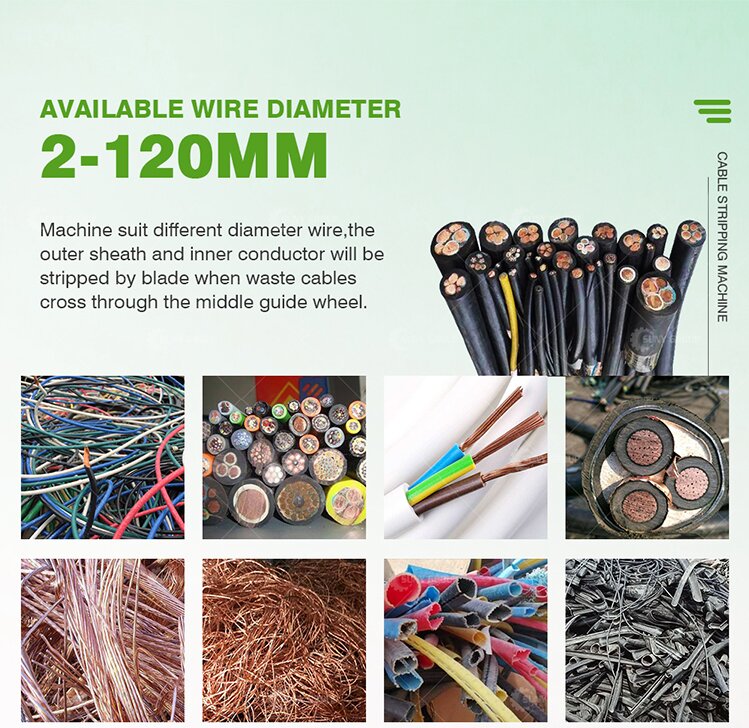

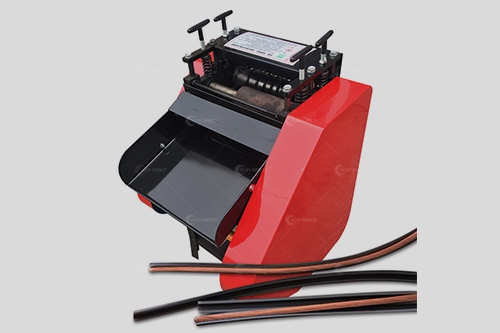

Wire stripping equipment is a machine used to remove insulation or casing from wires, cables, and other similar materials. It helps prepare wires for recycling, reuse or further processing. There are many types of wire stripping equipment, including manual, semi-automatic and fully automatic machines. Say goodbye to manual labor and embrace an automated future. Automatic wire stripping machines strip wires quickly and accurately without manual intervention.