In the field of waste cable recycling, efficient and high-quality equipment is the right assistant that practitioners dream of. Recently, our factory welcomed a customer from Australia, and a wonderful experience with a multifunctional cable stripping machine began.

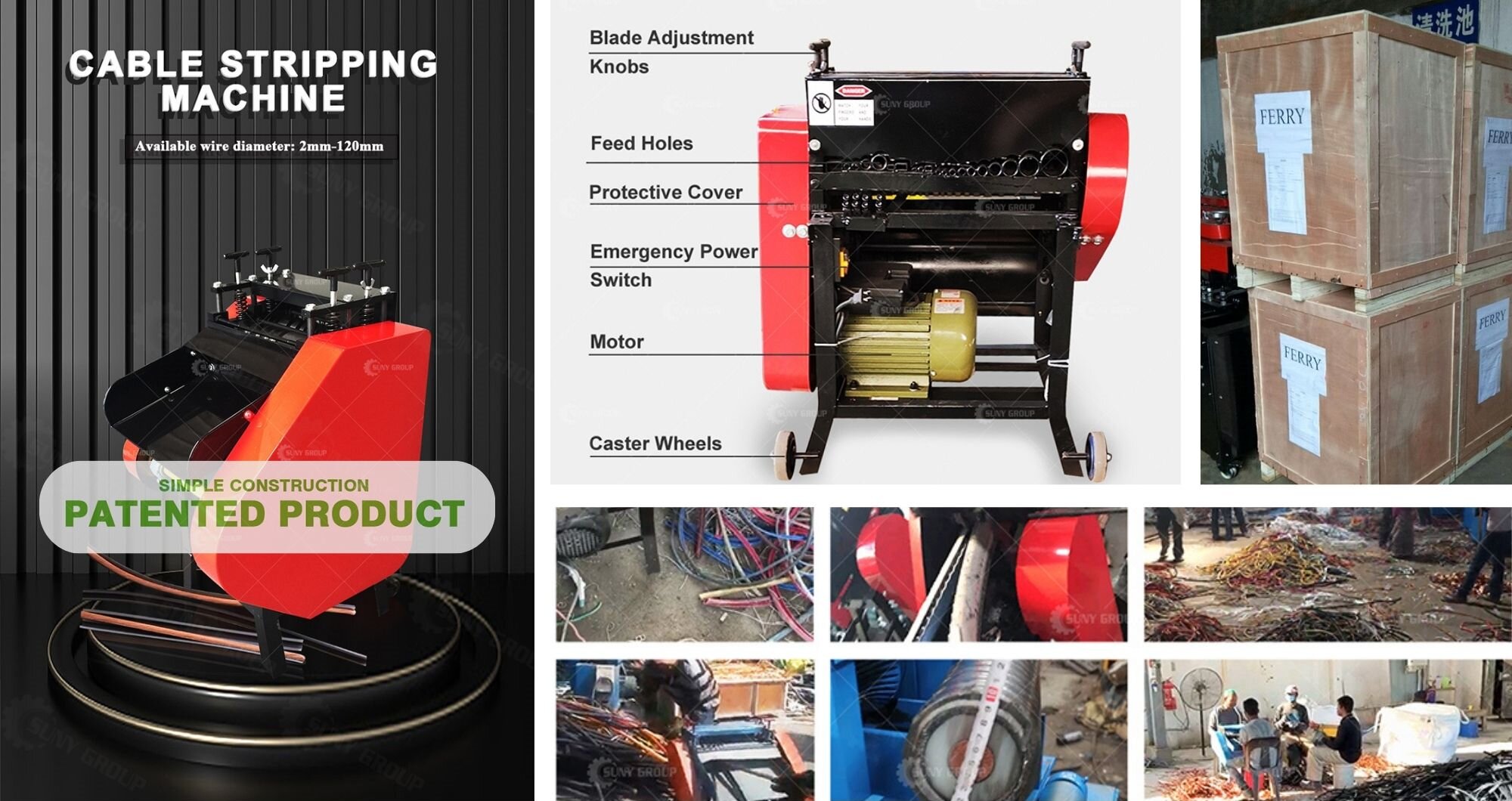

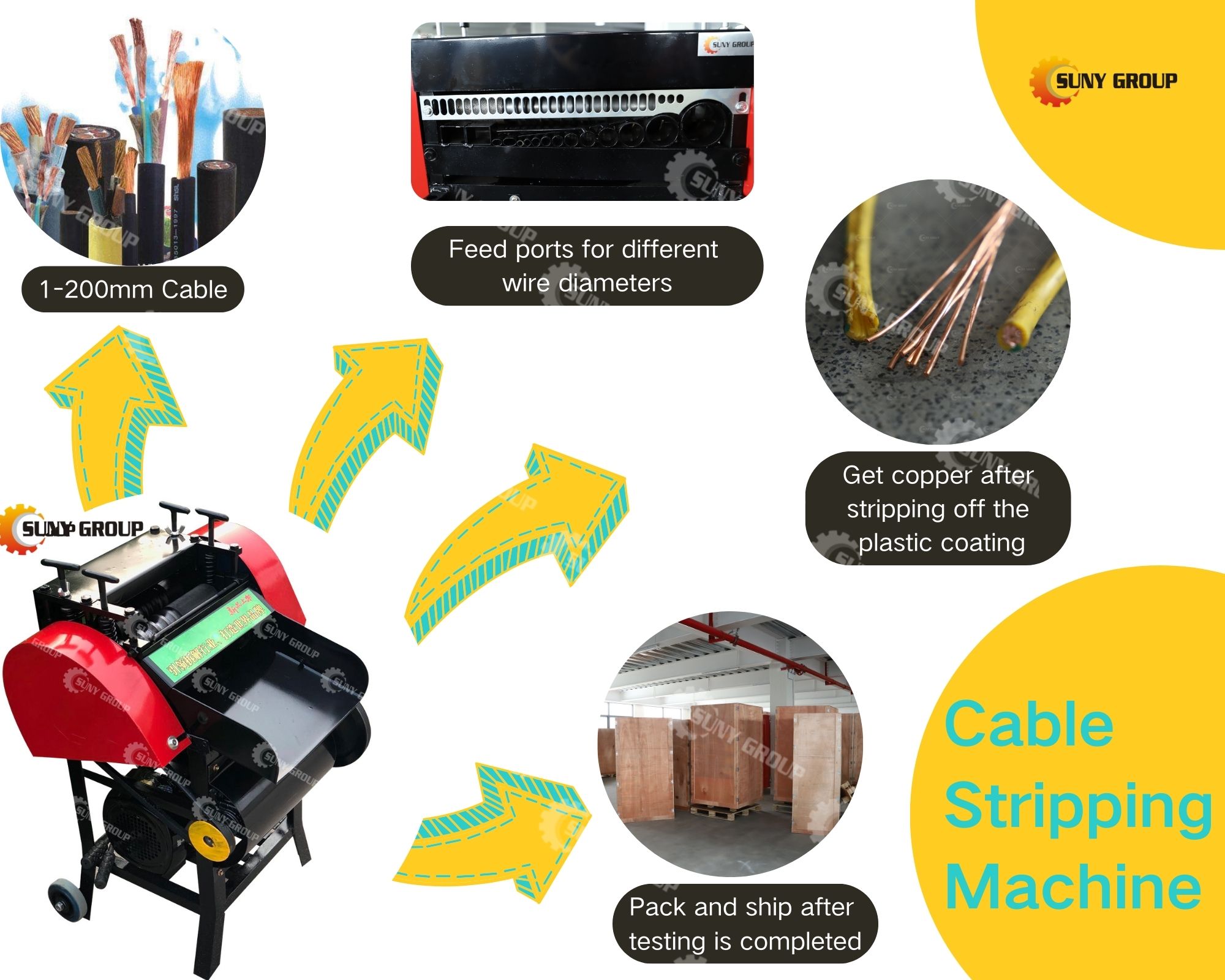

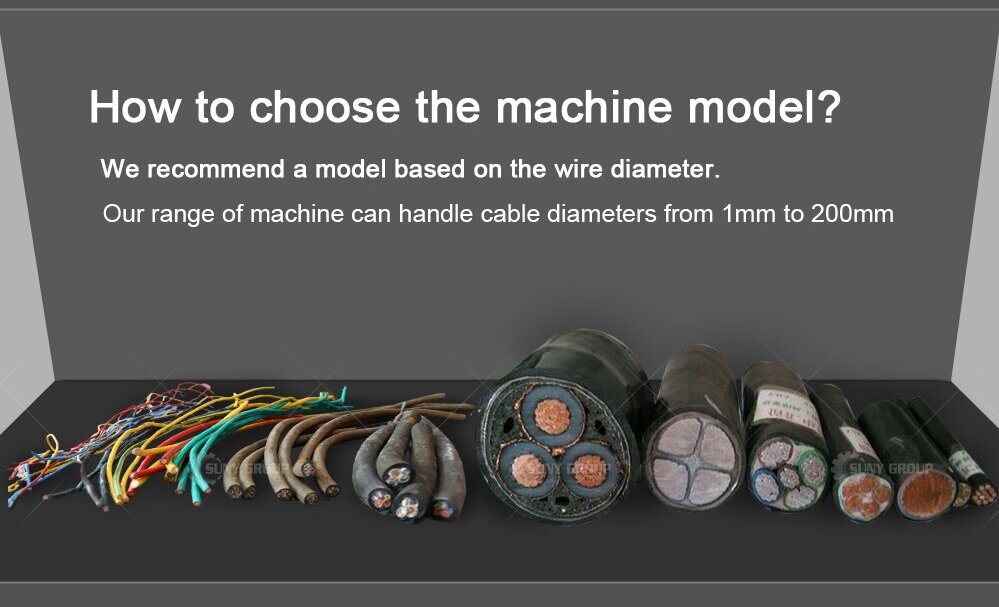

This Multifunction Cable Stripping Machine is a product developed and optimized by our company after years of research and development, specially designed for the recycling of waste cables, which can efficiently and accurately strip metal and plastic materials from cables and realize the reuse of resources. By stripping cables of different diameters, the machine shows high stability and handling capacity, which can effectively improve production efficiency and reduce labor costs.

ZY-CS120 Multifunctional cable stripping machine

The equipment has passed CE certification, and the core component blades are made of D2/SKD-11 high-quality materials to ensure that they remain sharp and durable in high-frequency use, and toughly cut through the cable sheath, so that the internal cables and the sheath are separated sharply, and the degree of cleanliness of the material far exceeds the customer’s expectations, and there is almost no residual impurity, which greatly saves the subsequent clean-up process. In addition, the low power consumption of the equipment, only 3 kW, stable operation, and low noise, are very in line with the needs of modern environmental protection production. It supports cable feed diameters ranging from 10 mm to 120 mm, with a processing capacity of 100 to 2,000 kilograms per hour, which is not only suitable for large-scale industrial production but also flexible enough to cope with small and medium-sized cable recycling needs. With a weight of 570 kg and a small footprint of 64cm x 78cm x 115cm, the compact design of the machine makes it easy to integrate into customers’ existing production lines.

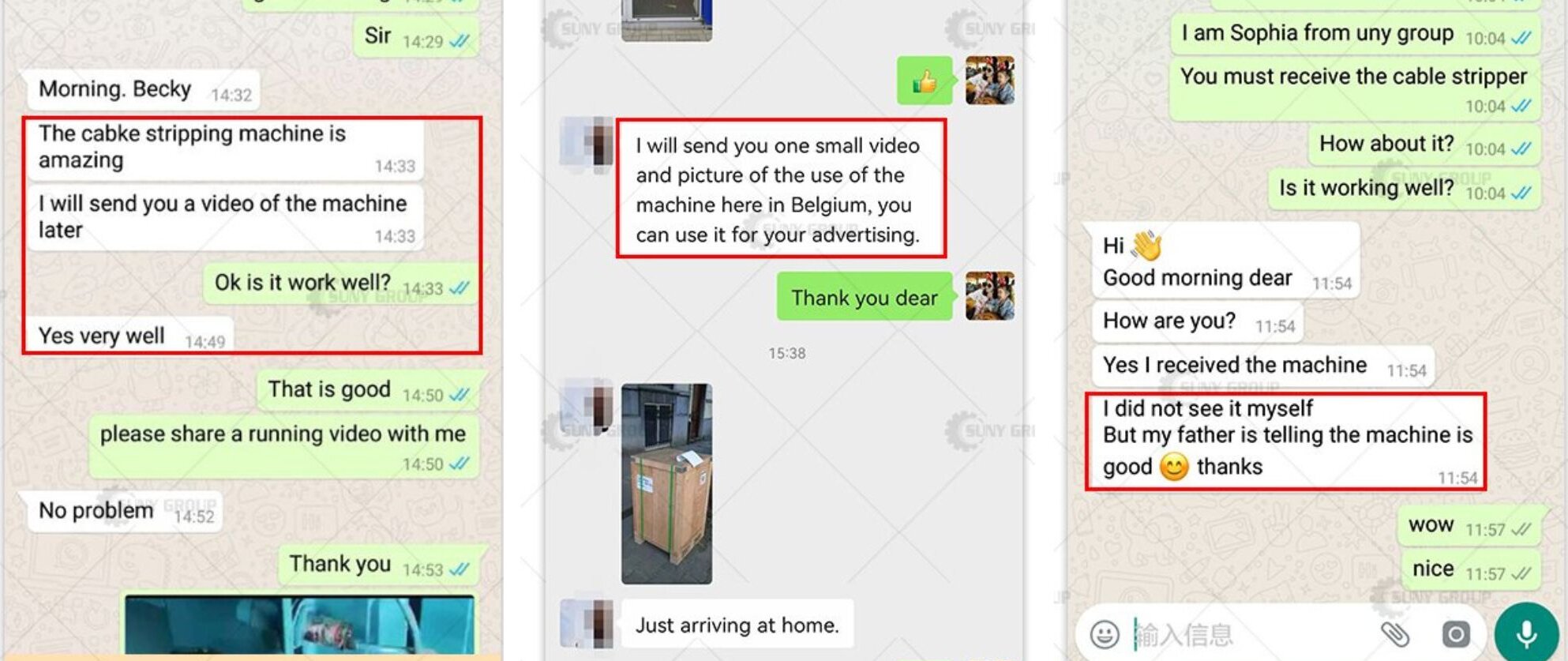

It is also worth mentioning that the machine comes with a 1 YEAR warranty for a worry-free after-sales service. After witnessing and experiencing the machine with their own eyes, the customer was so impressed with the performance and quality that they immediately decided to purchase several sets of the machine, ready to be put into the local waste cable recycling business.If you have any questions or need further information, please feel free to contact us. Our contact information is as follows:

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com