In recent years, entrepreneurs have chosen to join the cable recycling industry to cope with the e-waste crisis and find business opportunities in it. The global recycled copper market is expected to reach a market valuation of USD 87,960.1 million by 2027, expanding at a reasonable CAGR of 2.9% during the forecast period (2021-2027). Generous market returns have promoted rapid progress in recycling technology.

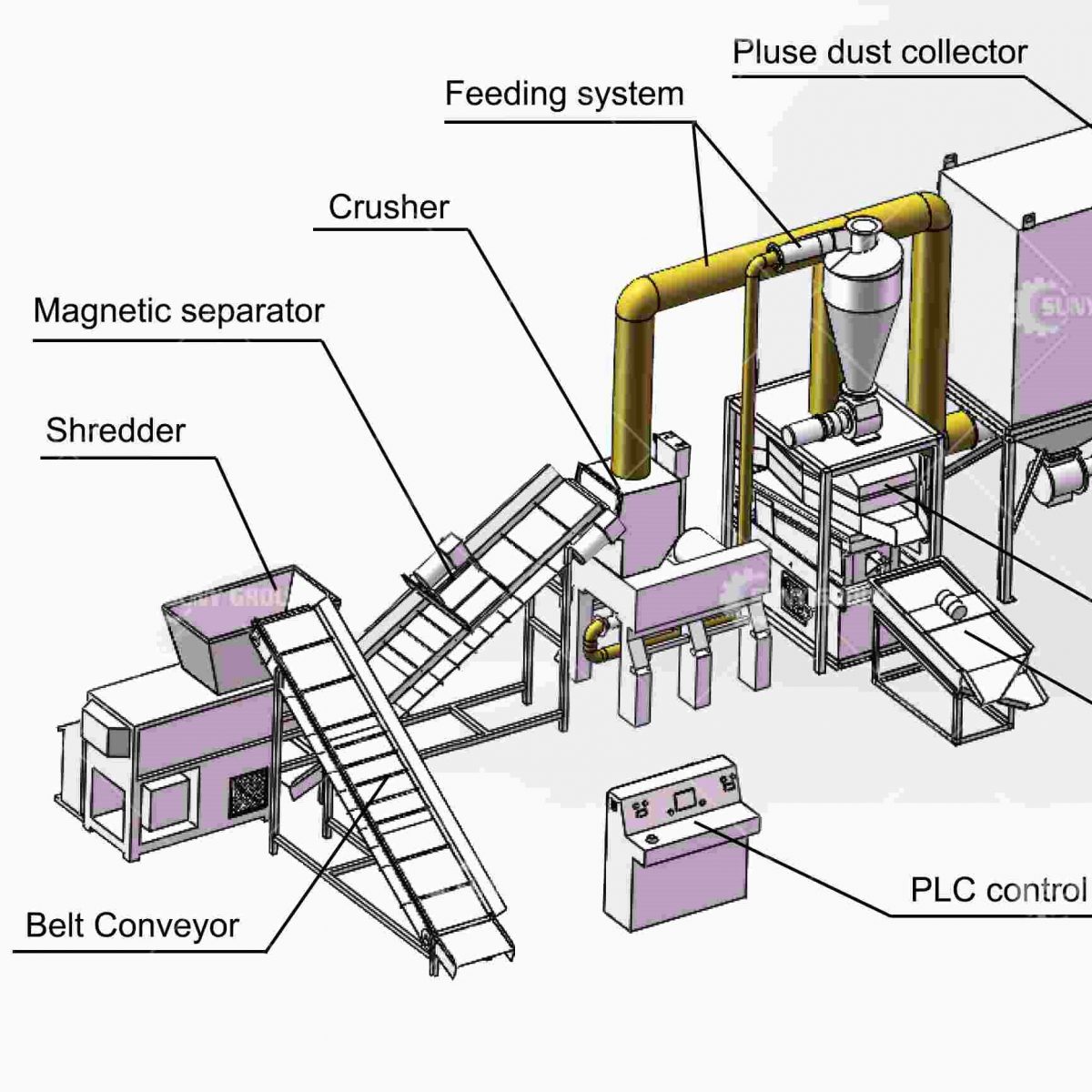

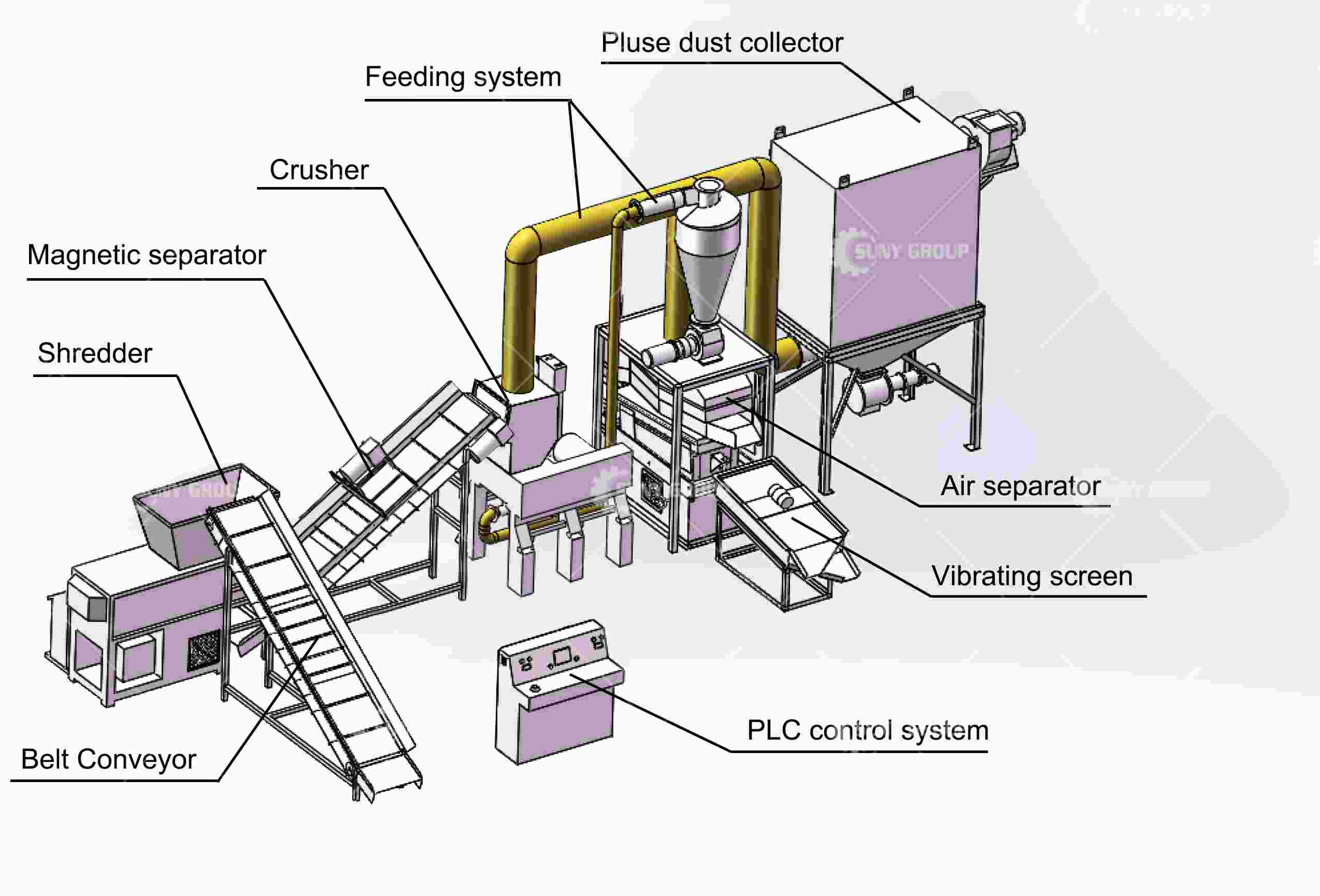

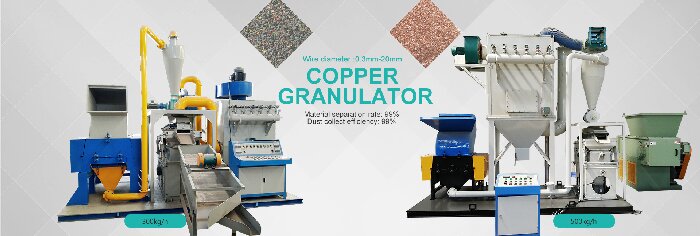

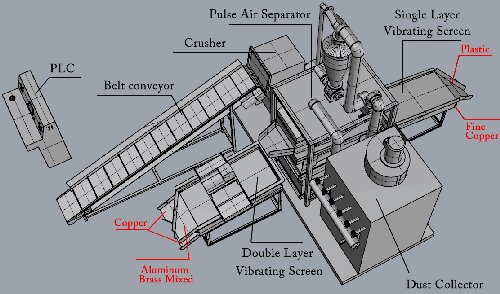

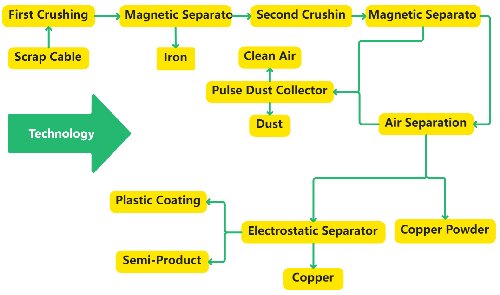

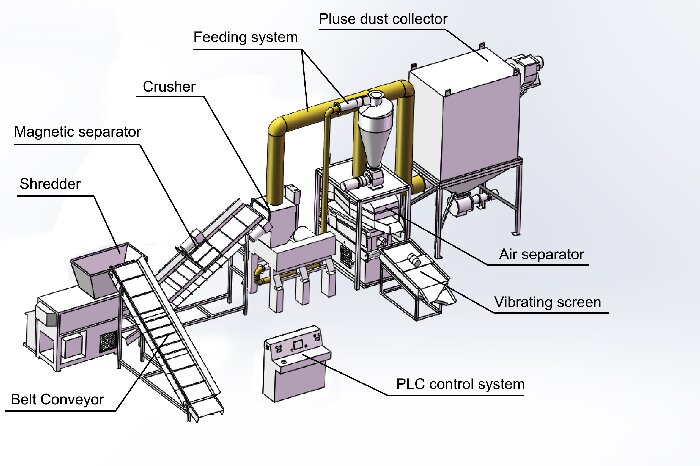

Follow the content of the article to see the optimization and changes made by our company’s new cable/wire recycling machine. First, we take a copper wire recycling machine with a capacity of 500kg/h as an example. We have made adaptive optimization in the traditional recycling machine process and installed a single-shaft shredder at the beginning of the production line for the purpose of processing For more complex materials (waste wires, cable wires, telephone wires, capillary copper wires and other mixed materials), the purpose of this is to meet the needs of different customers. For example, we have a customer case in Australia. They purchased this special model. The materials collected by the customer were messy, large in quantity, and difficult to handle manually. The efficiency of the traditional copper wire recycling machine was too low, and the recycled copper particles would have A large amount of plastic wire sheaths were difficult to sell, which increased the customer’s operating costs. Later, with our technical upgrades and help, this problem was solved and more profits were created.

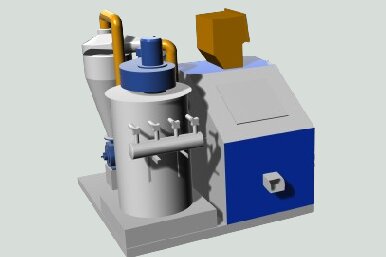

In addition, we have also optimized the PLC control system to make its operation interface simpler, switching smoother, enhancing work efficiency and reducing operating costs. In terms of motors, we use explosion-proof motors to cope with the complex power conditions in different countries, increase the safety of the production environment, have longer service life, and make maintenance more convenient. There is also a dust removal system. We have made a new optimization based on the original one. The new Pluse dust collector is more convenient and efficient, allowing dust and other harmful substances to be collected and processed in a unified manner to achieve the most harmless emission standards.

We will provide customers with better products and services with more enthusiasm and professional technology, and join hands with customers to embark on a new journey of copper wire recycling! If you want to know more complete technical details, please feel free to contact us, we will provide the most complete, most effective, and most suitable copper wire recycling solution for you.