The Copper Cable Granulator market is rapidly emerging as a key driver in the scrap copper cable recycling industry. The primary function of this equipment is to efficiently separate copper and plastic from scrap cables for reuse of copper. The market is expected to reach billions of dollars by 2025 with the stringent enforcement of environmental regulations and rising demand for resource recycling.

The recycling of copper, an industrially important metal, not only reduces the consumption of mineral resources but also lowers carbon emissions. Against this backdrop, the Copper Cable Granulator is gaining importance. The construction and upgrading of infrastructure in both emerging and developed markets requires large quantities of copper, especially in the power and communications sectors, where copper cables are an essential material. This continuously growing demand is providing a strong impetus to the Copper Cable Granulator market.

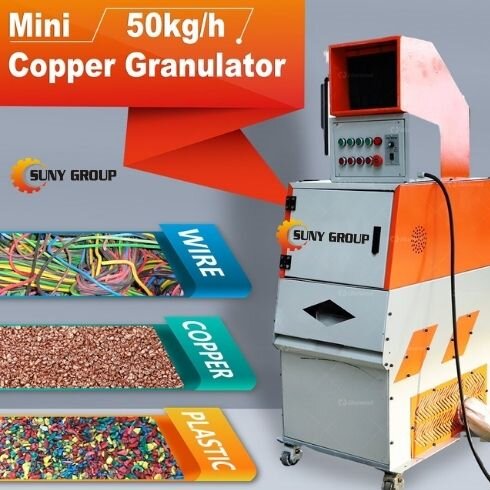

Continuous technological advancement is also an important factor in the development of the market. In recent years, Copper Cable Granulator has seen a significant increase in equipment efficiency and automation, which not only reduces operating costs but also improves recycling rates and makes the disposal of copper wire scrap more cost-effective. Copper Cable Granulators can efficiently separate copper and plastics from cables in the electrical and telecommunication industry, where the demand for high-quality copper is widespread. This is essential for the construction of power transmission and communication networks.

With the rapid growth of the electric vehicle industry, the demand for copper in the automotive sector is also increasing. The batteries, motors, and cables in electric vehicles require large quantities of copper, providing new growth drivers for the Copper Cable Granulator market. The manufacturing and electronics industries also have a pressing need for copper recycling. The replacement of electronic products and the continued growth of the manufacturing industry require large quantities of copper, further fuelling the adoption and expansion of Copper Cable Granulator equipment.

The rapid growth of the Copper Cable Granulator market is mainly attributed to the strengthening of environmental regulations and technological advancements. The focus of governments on environmental protection has led companies to look for greener ways of production, and recycling copper is one of them. At the same time, technological advancements in equipment have increased the efficiency and economy of copper wire recycling, further accelerating the market expansion. In conclusion, the Copper Cable Granulator market has a promising future. It is not only in line with the global trend of sustainable development but also provides important support for the efficient use of resources and the realization of environmental goals. If you also need a Copper Cable Granulator, please feel free to contact SUNY GROUP for inquiry.