As one of the countries in the world that attaches the most importance to environmental recycling, especially the treatment and recycling of electronic waste. Recently, we were fortunate to welcome five customers from South Korea to conduct in-depth inspections and technical discussions on the cable recycling equipment of our company Suny Group. The customers were impressed by the technical strength and production capacity of our company Suny Group and expressed their willingness to cooperate with us in the near future.

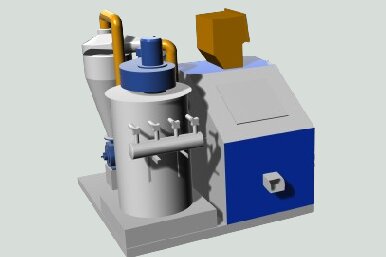

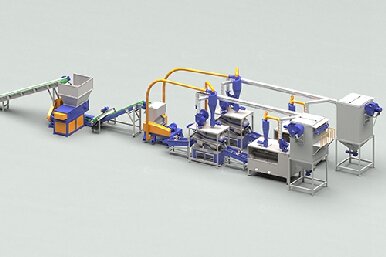

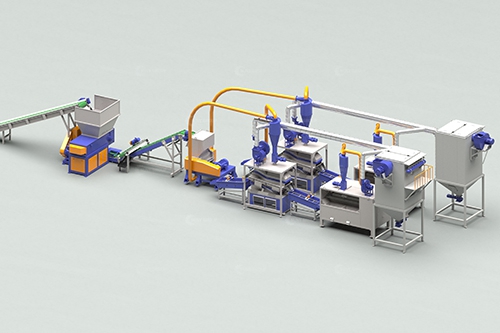

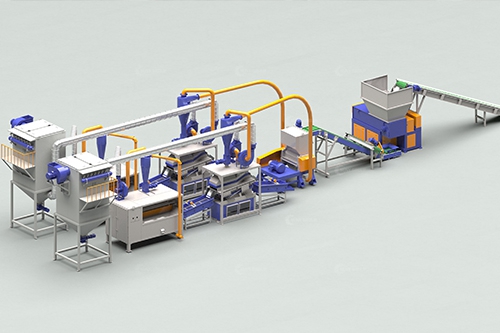

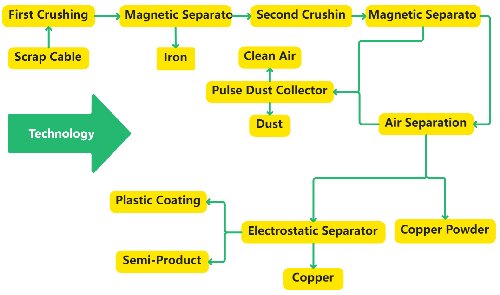

In the conference room, our professional technicians had an in-depth exchange on the technical details of the cable recycling equipment. By projecting the structure diagram and working principle of the equipment, our technicians explained in detail how the equipment can efficiently process various types of cables and achieve effective recycling and utilization of resources. The customer expressed great interest and recognition in the innovative design and efficient capabilities of the equipment.

cable recycling equipment

Subsequently, our technicians led the customer on a field visit to the factory and a detailed inspection of the machinery and equipment. On site, the customer witnessed our advanced production facilities and sophisticated processing technology. Our team of engineers showed the customer the various components of the cable recycling equipment, from the main mechanical structure to the key control system, and explained and demonstrated them in detail one by one.

The customer spoke highly of the equipment operation on our production line, especially in terms of equipment stability and production efficiency. They said that this field trip gave them a deeper understanding of Suny Group’s technical strength and product quality, and they are full of confidence in future cooperation. If you are interested in Suny Group’s cable recycling products and services, or have any questions, please do not hesitate to contact our team immediately.