On this special day dedicated to honoring the hard work of every laborer, all of us at SUNY GROUP extend our sincerest greetings and best wishes to those striving in various industries!

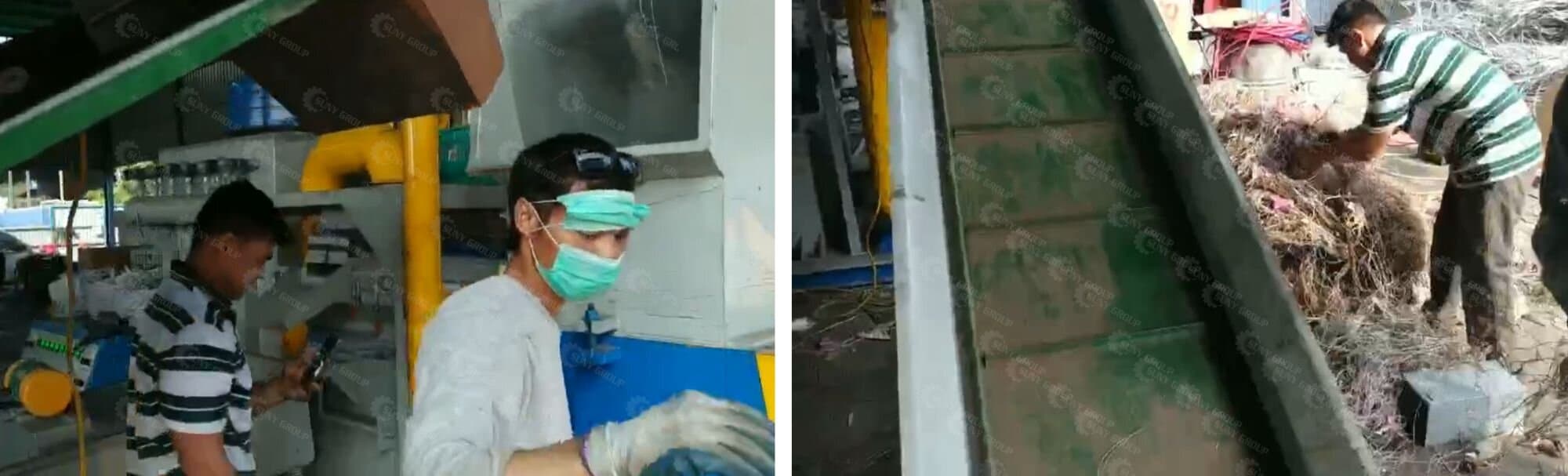

Scarp Cable Recycling Equipment

Holiday Schedule: In accordance with the national public holiday schedule, SUNY GROUP will be closed from May 1, 2025 (Thursday) to May 5, 2025 (Monday), totaling 5 days.We will resume normal operations on May 6, 2025 (Tuesday).

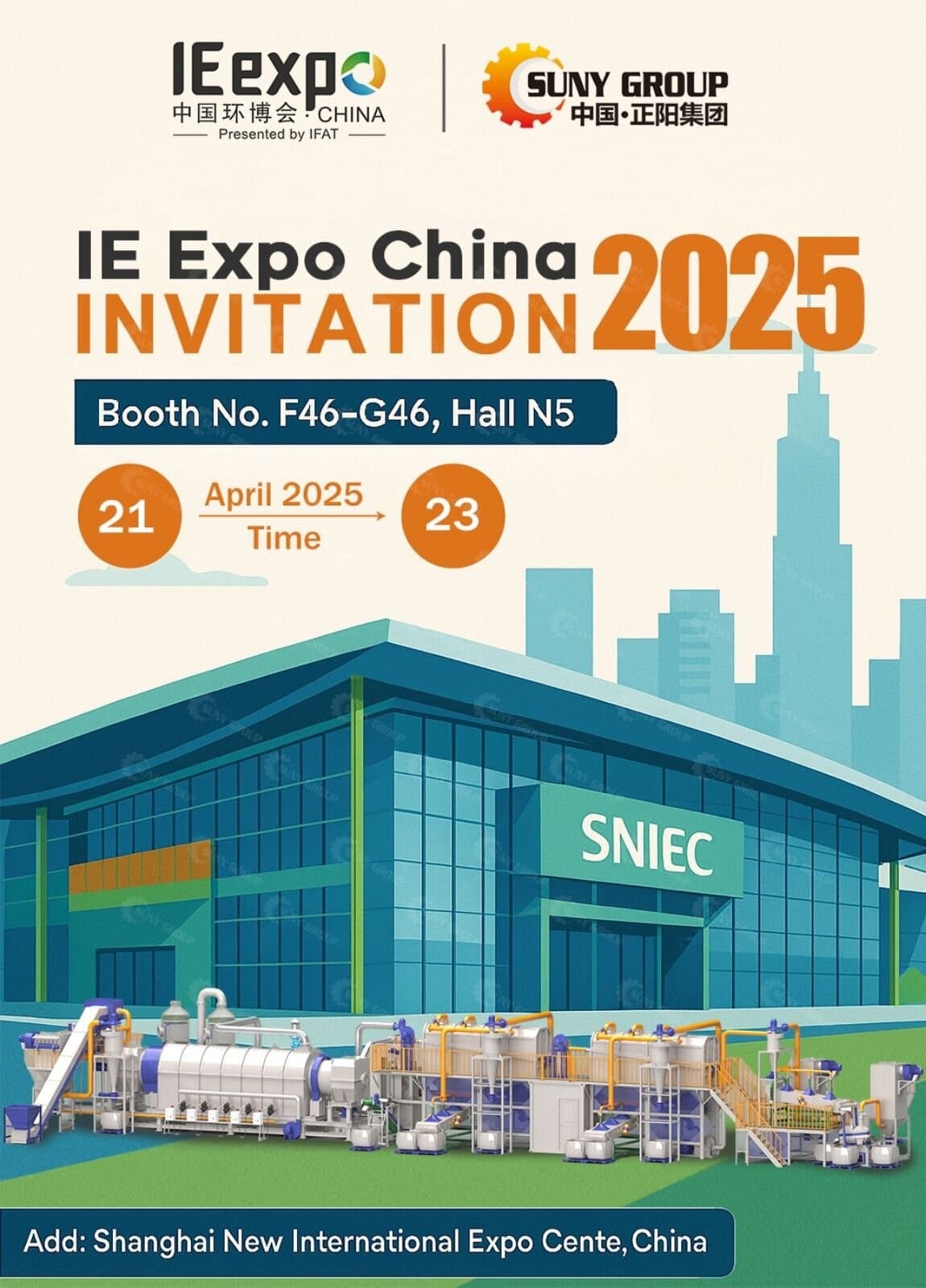

During the holiday, if you have any inquiries, feel free to contact us via email or leave a message on our website. We will respond as promptly as possible.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com