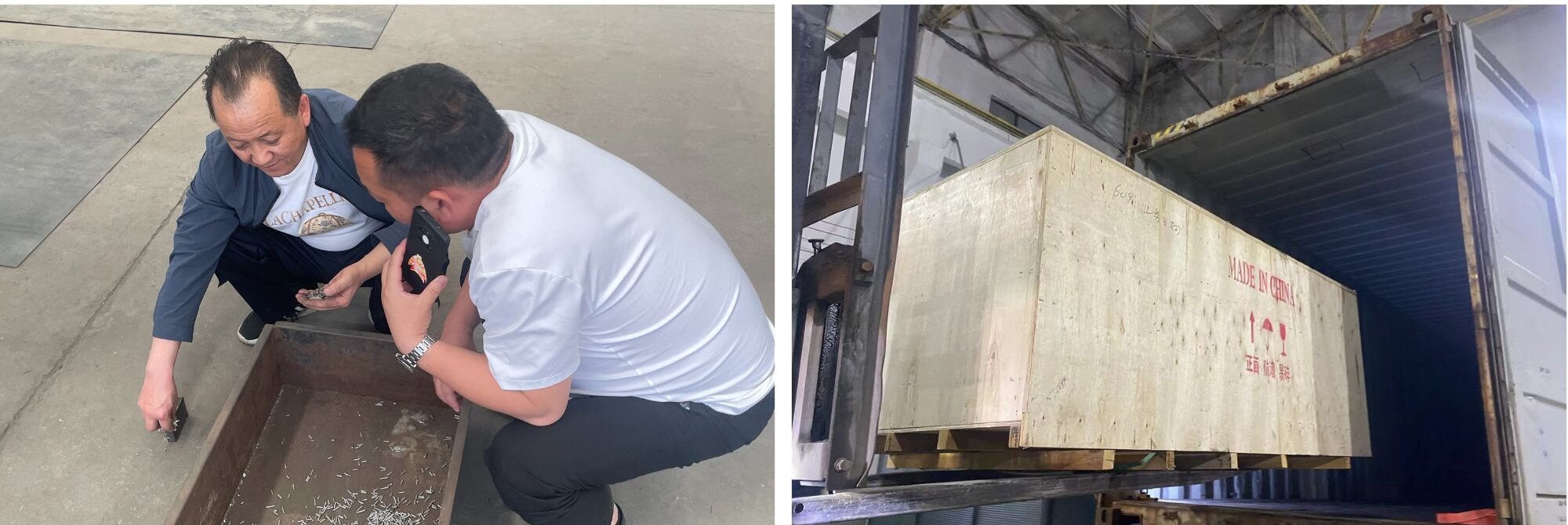

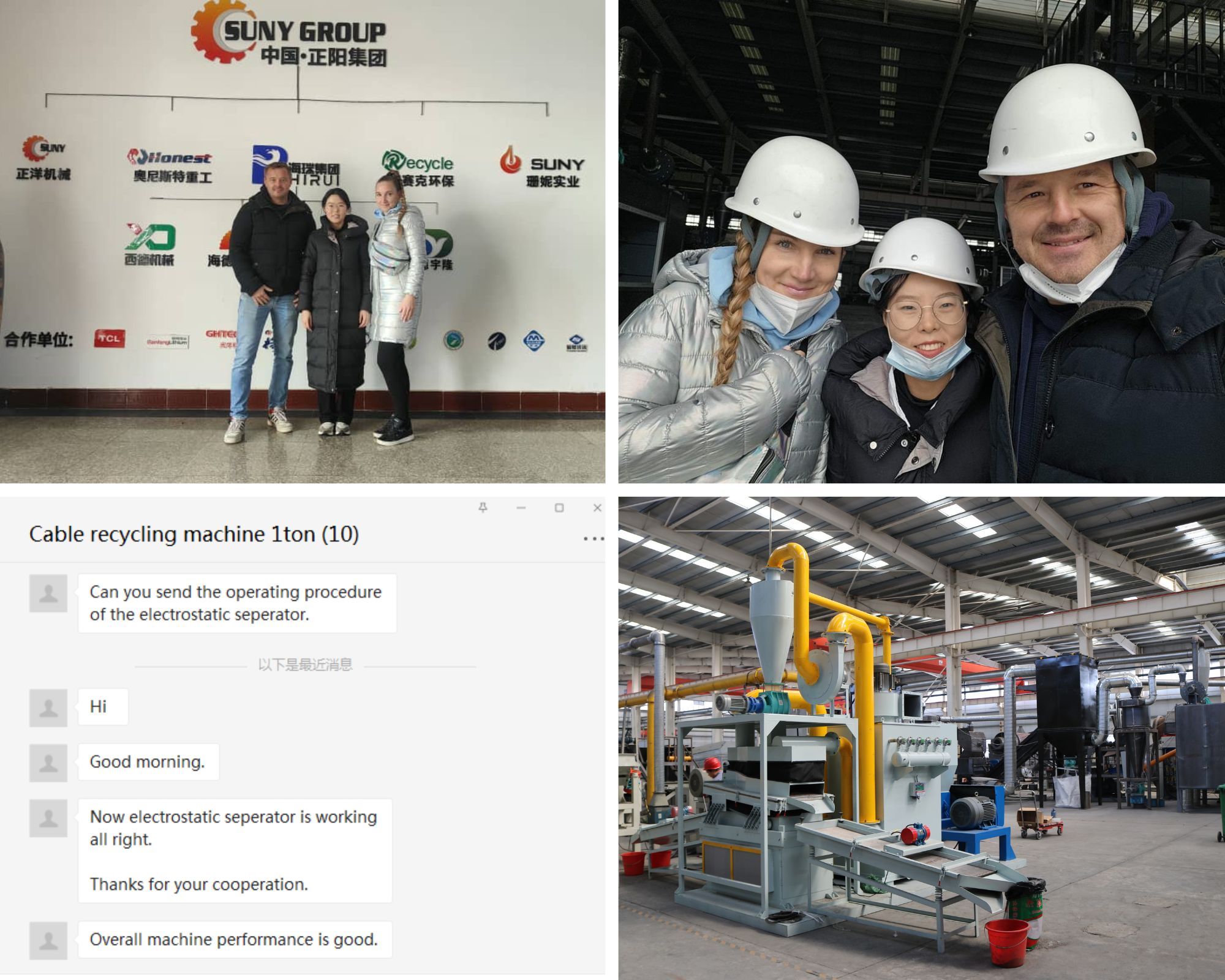

In May 2024, Suny Group is destined to be extraordinary. From the beginning of the month to now, our company has actively appeared in two major industry exhibitions, demonstrated our strength and innovation, and achieved remarkable results. And now, we are about to usher in the climax of our third exhibition – we welcome N-EXPO 2024, which will be held at the Tokyo International Exhibition Center from May 22 to 24. We are waiting for cordial communication with you at the just-opened N-EXPO exhibition.

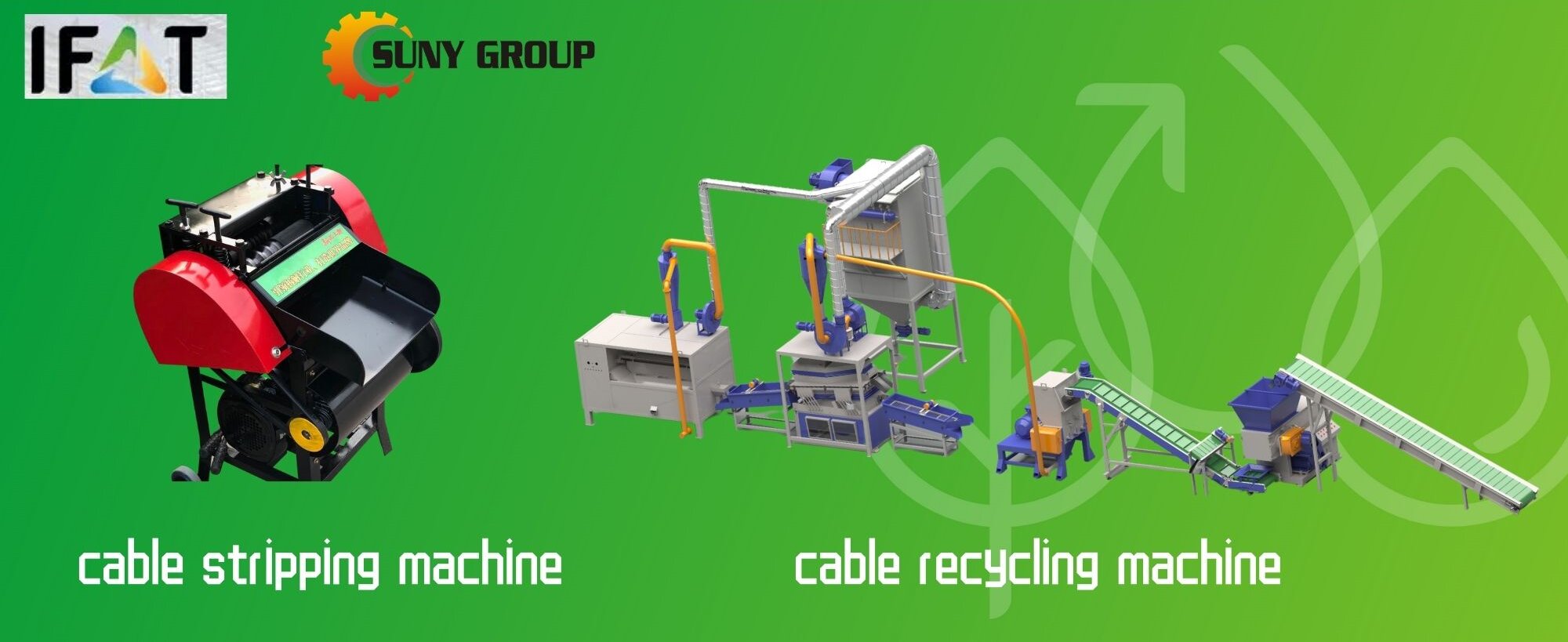

N-EXPO, as the Tokyo Environmental Exhibition, is one of the most influential exhibitions in the global environmental protection field. This exhibition brings together environmental protection companies and professionals from all over the world to discuss and display the most cutting-edge environmental technologies and solutions. Suny Group’s booth number in this exhibition is A211. With the theme of “Innovation and Environmental Protection”, we comprehensively displayed our latest technologies and products, including cable stripping machine, cable recycling machines and copper wire recycling machines, jelly wire recycling machine, Steel core aluminum stranded wire recycling machine.

The first two exhibitions were full of fruitful results, which not only helped us confirm the important position of the company’s technology, but also made us more clear about our development direction and goals. And now, the last exhibition in May 2024 is in full swing. Here, we eagerly look forward to your visit, visit and exchange at our booth. The team at Suny Group is ready and ready to welcome you. This May, let us meet at the intersection of dreams and passion!