Our Chinese New Year holiday will take place from February 13th to February 23rd, 2026. During this period, factory production and shipment activities will be temporarily suspended. Normal manufacturing operations will resume on February 24th, 2026.

Although our production floor will be at rest, our commitment to sustainability continues. Throughout the holiday, our team remains available for technical consultation, process discussions, and preliminary system planning, ensuring that project ideas and collaboration continue to take shape. Detailed engineering design, manufacturing, and delivery arrangements will be carried out immediately upon the resumption of factory operations.

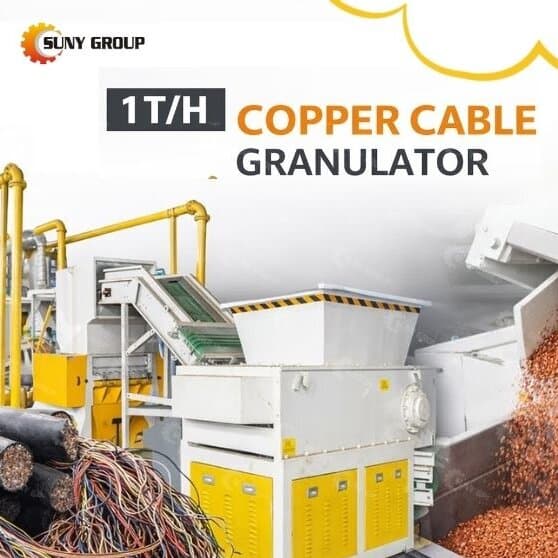

To support customers planning recycling projects for the year ahead — including Tetra Pak / Milk Carton recycling systems, cable recycling systems, aluminum-plastic separation lines, baby diaper recycling machine, and composite packaging recycling solutions — we encourage early order confirmation. Orders finalized prior to the holiday will be given priority in post-holiday production scheduling, helping projects move forward without delay.

SUNY GROUP remains committed to providing reliable recycling technologies and professional support to customers worldwide. We sincerely appreciate your continued trust and cooperation and look forward to advancing sustainable recycling solutions together in the coming year. We wish all our partners a prosperous, successful, and healthy Chinese New Year.

We are a professional manufacturer of recycling machinery and equipment. Our professional technology and considerate service will provide you with the most reasonable personal solution. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com