With the increasing demand for recycling of used wires and cables, the issue of how to process Aluminum Core Stranded Wire (ACSR) more efficiently has been a major concern. Now, a revolutionary Aluminum Wire ACSR Waste Recycling Machine has been developed for this purpose, bringing a new light to the industry by demonstrating superior performance in the precise separation of aluminum and steel.

Aluminum conductor steel reinforced, also known as ACSR, is a reinforced wire made of single or multiple layers of aluminum strands stranded outside of a galvanized steel core. Aluminum conductor steel reinforced is made of stranded aluminum and steel wires, with a steel core inside and a steel core outside. Core”, the outside is by the aluminum wire through the stranded way around the steel core. It is mainly used in the power and transmission line industry.

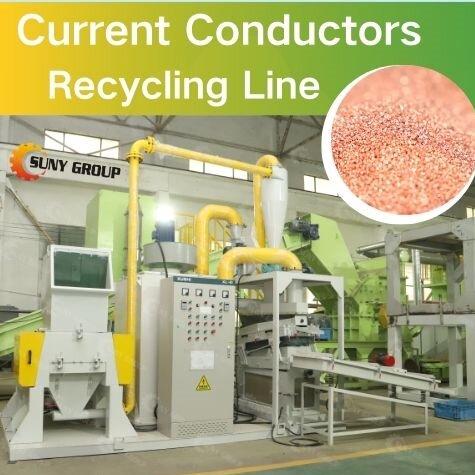

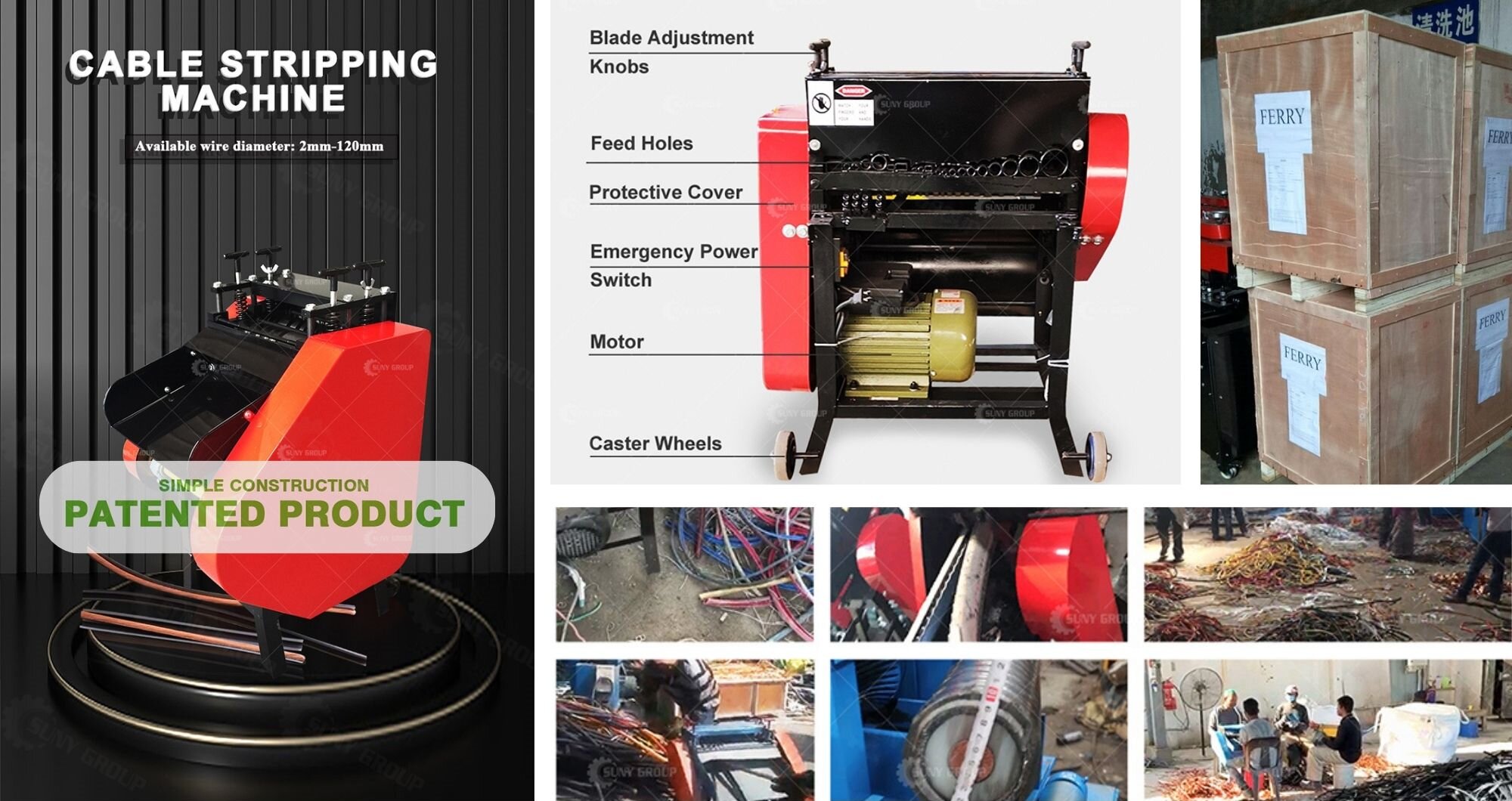

Externally, the recycling machine is well-designed, with reasonable dimensions complemented by high-quality materials. The weight of the machine is about 2000kg and it can recycle 50 meters of aluminum conductor steel reinforced per minute. The machine is equipped with a speed reducer which can be changed in three gears and adjust the speed of the knife rollers so that the material can be formed into uniform sizes of 10mm, 20mm, and 50mm. The overall structure is scientific, the feeding system, discharging system, and separating system are well laid out and closely connected, constituting a smooth operation system. It is like a highly efficient factory, where each part plays a key role in the recycling process of waste aluminum conductor steel reinforced.

Aluminum Wire ACSR Waste Recycling Machine

The working principle of this machine is unique. When the waste aluminum conductor steel reinforced enters the machine (inlet: 200mm diameter (multi-strand feeding is possible)), it will be shredded by the knife rollers into uniform sizes, and then through the outlet to the separation system, where it will be separated by magnetic separation to get the aluminum and steel, with a separation rate of up to 100%, which can be sold directly. In terms of operation and maintenance, the design team of the Aluminum Wire ACSR Waste Recycling Machine has taken into account the actual needs of the users by providing a simple operation procedure and a comprehensive maintenance program. Operators of the machine can master the machine with minimal training, and troubleshooting common problems is a breeze.

In summary, the Aluminum Wire ACSR Waste Recycling Machine is not only technologically advanced, it is also an important tool in the promotion of the circular economy. It brings new life to the recycling industry by accurately separating aluminum and steel. We welcome inquiries from customers interested in environmental protection and resource recovery.If you have any questions or need further information, please feel free to contact us. Our contact information is as follows:

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com