In the world’s waste management, electronic waste is the fastest growing part of the waste stream, mainly due to the high demand and high elimination of electronic products in modern society. In fact, 86% of the world’s electronic waste is sent to landfills and incinerators, which is not good for the earth and the reuse of resources. This article will explain one of the waste materials in electronic waste – waste cables. How to deal with and recycle a large number of cables? Only in this way can it be beneficial to the earth and the reuse of resources. Do you need to buy professional cable recycling equipment?

Before starting this money-making project, please confirm whether you have enough waste cables? If your reserves are small, please think carefully before starting this project, instead of starting blindly. Then, for those individuals or companies with a large number of waste cables, congratulations, you will make a lot of money through the waste cable recycling business. What is the finished product you can get by recycling waste cables? The answer is copper particles and plastic outer packaging (only considering the recycling of copper cables). You will ask me why recycling cables can make a lot of money? Then please ask about the local price of recycled copper, and you will know that you will make a lot of $$$$$$$!

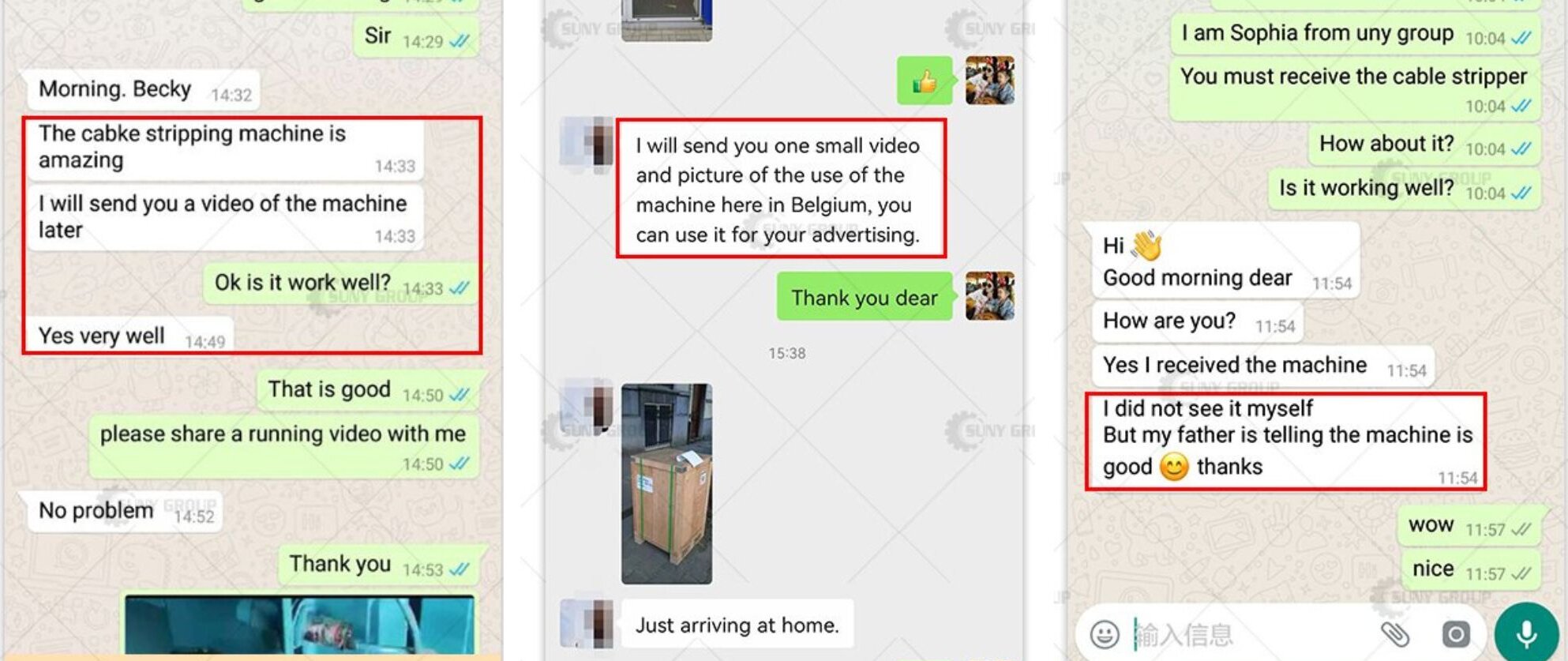

You can start recycling in the simplest way, through a cable stripping machine. Put the waste cables through this machine, and then you will get clean copper and plastic packaging separated. When you accumulate a certain weight, you can sell it to merchants who specialize in purchasing them. Any metal recycling center will be happy to accept your copper core wire, and the more the better, earn your first bucket of cable recycling $$$$$$$$! SUNY GROUP copper wire stripping machine has the advantages of Simple operation and safe use. The blade adjusting rod is convenient to adjust the blade distance according to the wire diameter. Double stripping path with doubleknife, made the separation conplete, Scroll design at the outlet avoide the wire damage. There are round holes and squareholes of different sizes, which can strip wires with multiple center diameters. The blade adjusting rod is convenient to adjust the blade distance according to the wire diameter.

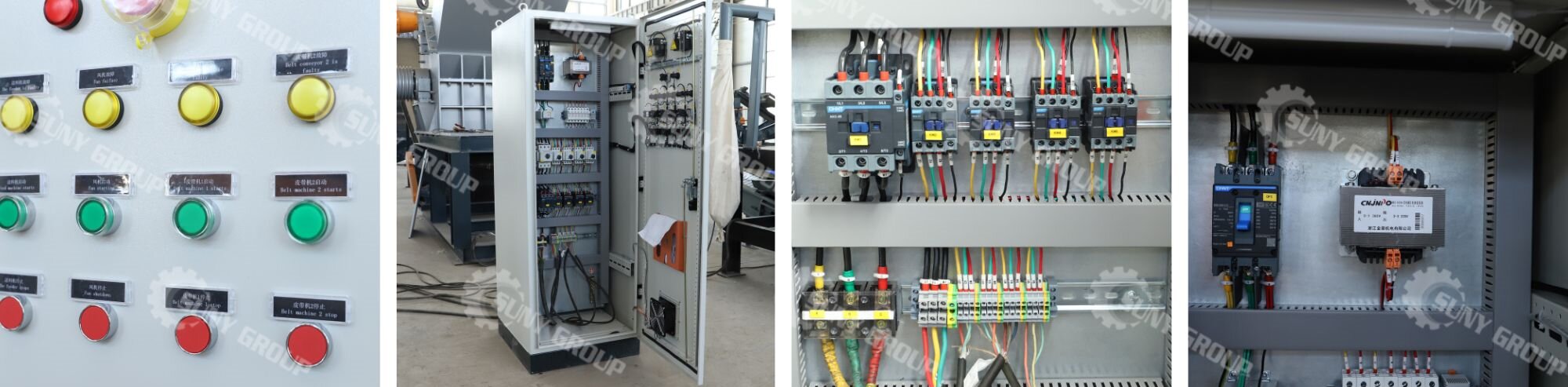

If you are not satisfied with a single, inefficient recycling process, you can also try to purchase a professional cable recycling plant. For example, SUNY GROUP fully automatic cable recycling plant. The device adopts an integrated design, compact design, small footprint, and easy to move. Just place it on a flat surface and connect it to a power source to operate it. The PLC control system makes the appearance simple and beautiful, and the operation is simple, and one person can operate it. Gravity separation adopts Italian air suspension separation technology, which can accurately adjust the vibration frequency and airflow of the material suspension according to different materials. The equipment is fully enclosed and equipped with an advanced pulse dust removal system, which can effectively collect dust during the production process and discharge it through the dust removal port. The company is also equipped with electrostatic sorting equipment to recycle the remaining copper in the plastic, ensuring that there is no plastic in the copper and no copper in the plastic.

Finally, do you need to buy professional cable recycling equipment? This depends on whether you have enough funds and available factory buildings. When you are ready, all difficulties cannot make you make money in cable recycling. If you are interested in our cable recycling products and services, or have any questions, please do not hesitate to contact our team immediately. We will wholeheartedly provide you with professional cable recycling solutions and provide you with the best service.