New Center

The Key to Profitability in Cable Recycling: Equipment Selection

January 9, 2026Industry experts note that the key to profitability in cable recycling lies not in labor intensity, but in efficient and precise material separation. Mixed and fine electrical wires—meaning bundles of various types and thicknesses of wires, often too small or complex to strip by hand—are commonly found in industrial scrap and electronic waste, and are difficult to process using traditional stripping methods. As a result, automated copper wire recycling lines—systems that perform mechanical shredding and separation without manual intervention—are increasingly being adopted as the industry standard.

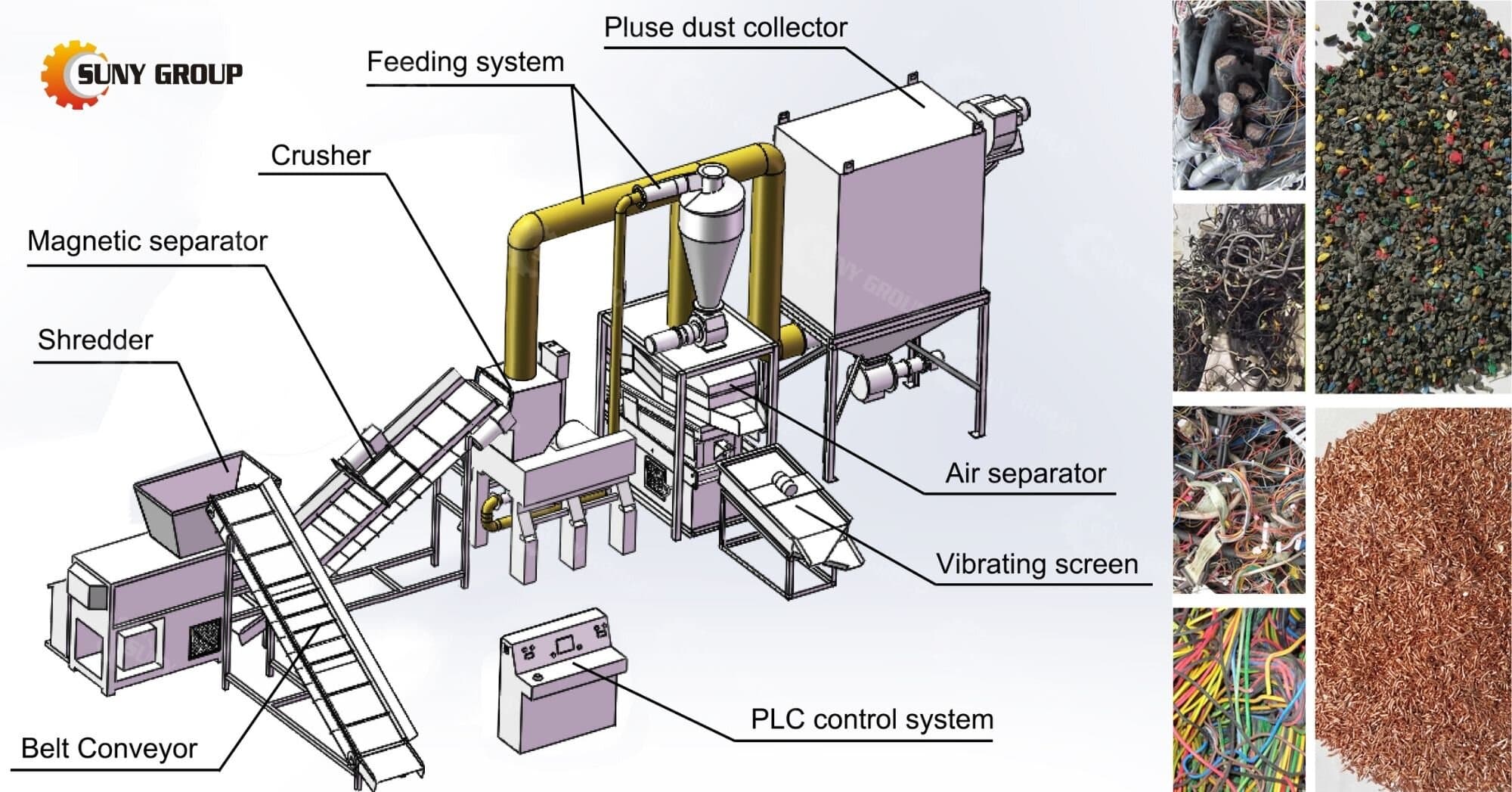

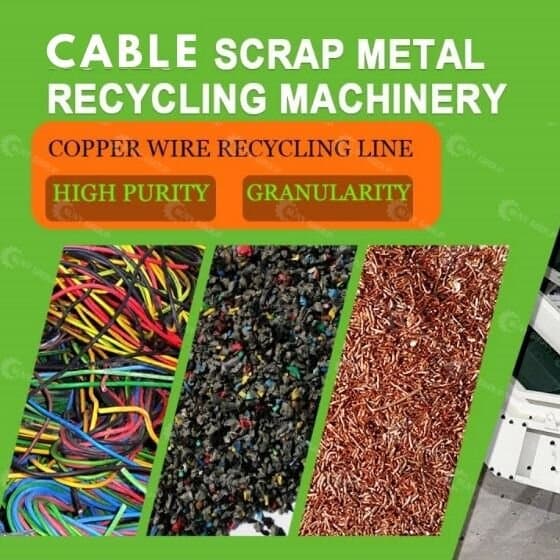

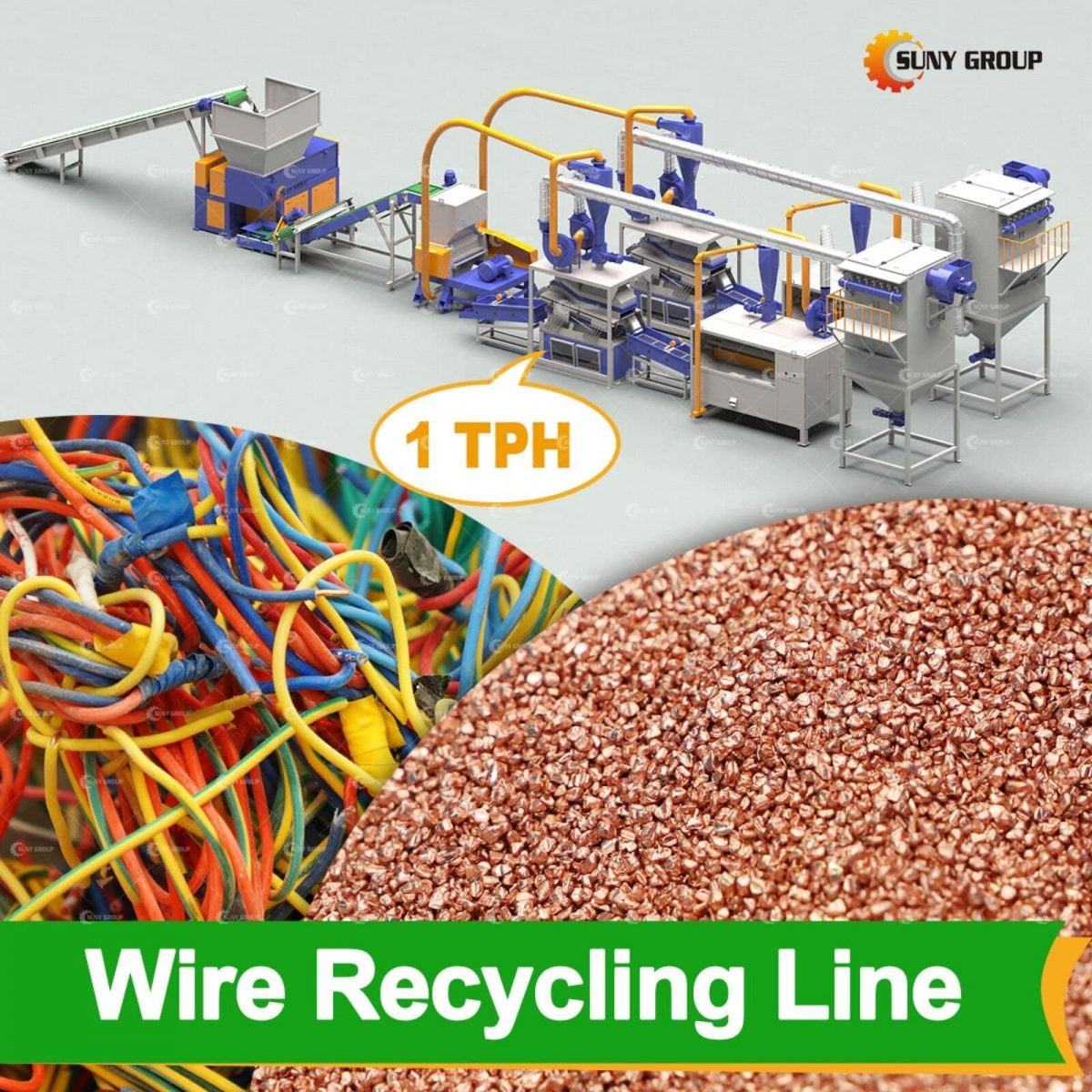

Modern copper wire recycling lines are designed to transform complex cable waste into clean, reusable raw materials. These lines use a fully integrated process—including shredding (cutting cables into small pieces), crushing (reducing pieces into finer fragments), magnetic separation (removing metallic particles with magnets), air separation (using airflow to separate materials based on weight), and screening (sorting fragments by size)—to separate copper from plastic insulation with high accuracy.

Advanced PLC control systems allow operators to monitor and adjust the entire process from a single interface, ensuring stable operation and consistent output quality. The result is high-purity copper granules with uniform size, suitable for direct resale or downstream processing, while plastic fractions are cleanly separated for further recycling.

Equipment Selection Becomes a Strategic Decision

With rising labor costs and stricter environmental regulations, equipment selection has become a strategic decision for recycling companies. Choosing machinery that does not match the cable type or processing volume can lead to low recovery rates, excessive material loss, and frequent maintenance issues.

Fully automated copper wire granulation lines are particularly suited for industrial-scale operations handling mixed, thin, or irregular cables. Although the initial investment is higher than basic solutions, recyclers report improved long-term returns due to reduced manpower requirements, higher copper recovery rates, and stable production performance.

The increasing adoption of automated cable recycling machinery reflects a broader shift within the recycling industry toward sustainability and efficiency. By maximizing material recovery and minimizing waste, modern recycling lines help reduce the need for primary copper mining while supporting circular-economy goals.

As the market continues to evolve, industry participants agree that investment in reliable, well-engineered recycling systems will play a critical role in shaping the future of cable scrap recycling. High-purity output, operational stability, and intelligent control are no longer competitive advantages—they are becoming essential requirements.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry