New Center

Jelly(Gel) Cable Washing Crushing and Copper Sorting Line

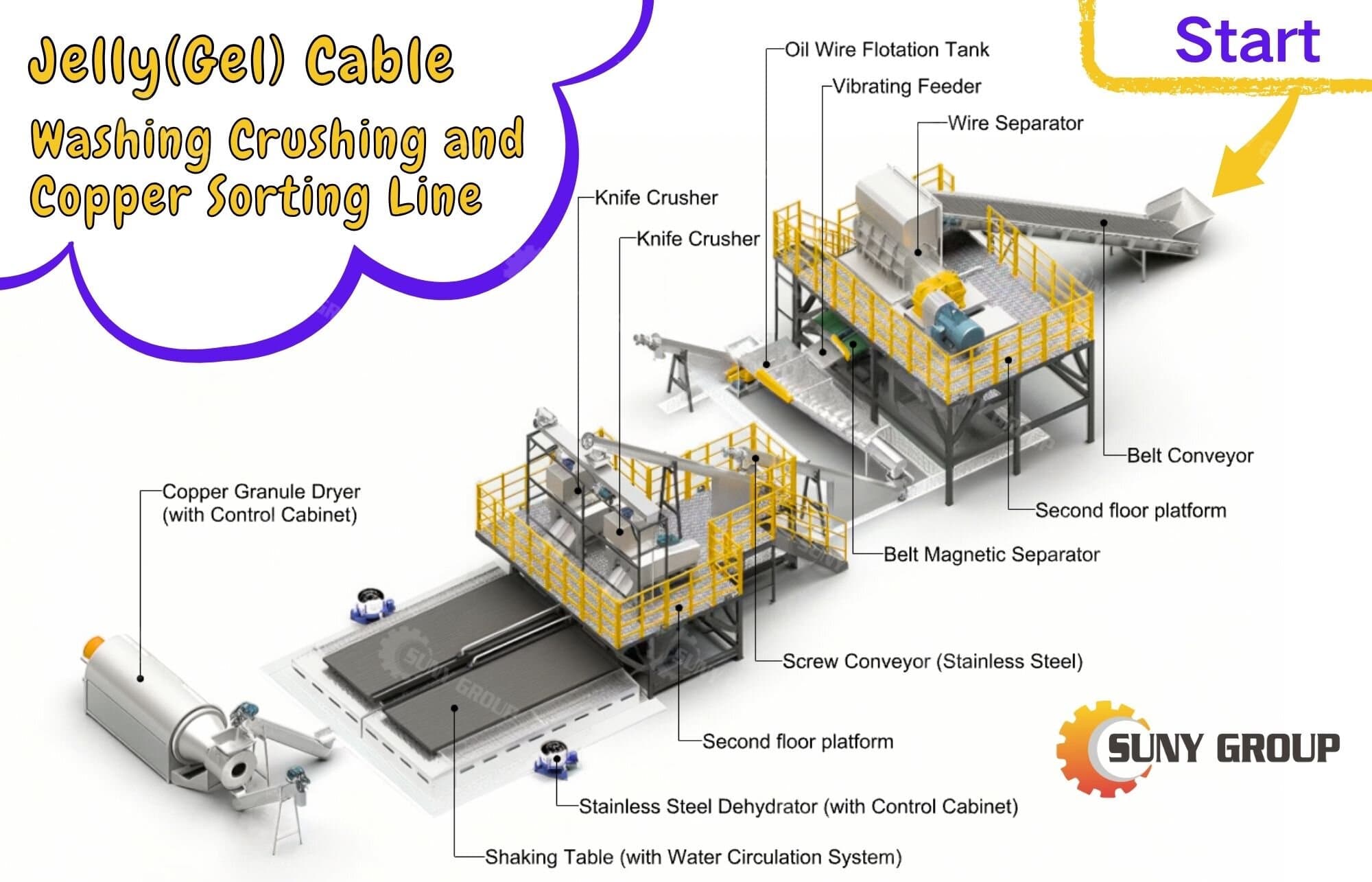

November 11, 2025The Jelly-Filled Cable Recycling Machine is designed to efficiently extract pure copper and recyclable plastic from jelly (gel) or oil-filled communication and underground cables. These cables, commonly used in outdoor telecom applications, contain sticky waterproof gel that makes separation difficult. Our fully automated 2–3 t/h recycling line combines crushing, washing, flotation, and gravity separation to ensure over 99% copper recovery purity, while maintaining eco-friendly operation through water circulation and dust control systems.

The process starts with a Belt Conveyor feeding cables into the Wire Separator (double-shaft shredder), located on the second-floor platform, for primary shredding. The shredded material is transferred through a Belt Magnetic Separator and Vibrating Feeder to remove iron impurities and ensure even feeding. The cables then enter the Oil Wire Flotation Tank, where the special washing system dissolves and removes jelly or grease using eco-safe cleaning agents. A Stainless Steel Screw Conveyor transfers the cleaned material to Knife Crushers (dual units) for fine crushing, reducing the material size to less than 2 mm for precision separation.

Jelly(Gel) Cable Washing Crushing and Copper Sorting Line

Next, the material passes through Stainless Steel Dehydrators (dual units) to remove excess moisture, before entering the Shaking Tables (dual units) with a Water Circulation System. Here, copper granules and plastic are separated by density difference, achieving a clean and high-purity copper output. Finally, the copper particles are processed through the Copper Granule Dryer (with Control Cabinet) for drying and collection.

This advanced recycling line ensures stable performance, continuous operation, and high automation, all controlled via a PLC system. Each component, from the shredding to the final drying stage, is designed for durability and easy maintenance. It’s the ideal solution for recyclers and cable recovery plants seeking maximum copper yield and minimal environmental impact from jelly or gel-filled cables. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry