New Center

How to Get Clean Copper Granules from Scrap Cables

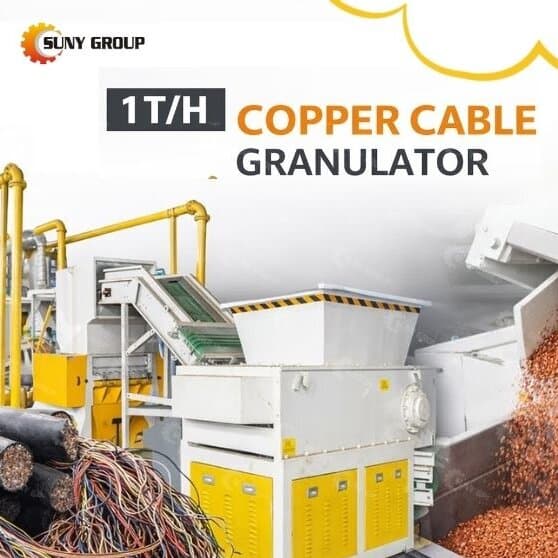

February 6, 2026Recovering clean copper granules from scrap cables is often described as a technical challenge, but in reality, the difficulty lies less in the material itself and more in how the process is designed and controlled. For recyclers handling large volumes of waste copper wire, manual stripping is slow, labor-intensive, and increasingly uneconomical. Mechanical granulation combined with physical separation has therefore become the mainstream solution, especially when dealing with mixed, fine, or irregular cables.

Scrap cables vary widely in structure and composition, including automotive wiring harnesses, household appliance wires, communication cables, and computer wires. These materials cannot be processed efficiently using a single, simplistic method. What ultimately determines the economic outcome is not the quantity of scrap fed into the system, but whether the operation can consistently produce copper granules that meet market purity requirements. Clean copper sells faster, commands higher prices, and requires no additional downstream processing.

In mature recycling markets, physical separation has largely replaced burning and chemical treatment. Unlike traditional methods, physical processes do not generate wastewater, toxic emissions, or secondary pollution. They rely on controlled crushing, airflow, screening, and density differences to separate copper from insulation materials. This makes the process more stable, more compliant with environmental regulations, and easier to scale for long-term operation.

The quality of the final copper output depends heavily on process details. Crushing must be carefully controlled: particles that are too large prevent full liberation of copper, while excessive grinding increases dust and metal loss. Separation efficiency also improves significantly when multiple stages are used rather than a single pass. Stable airflow is particularly important, as even small fluctuations can result in plastic contamination or copper loss. These details, often overlooked, are what distinguish clean, market-ready copper granules from low-grade mixed material.

Waste cables are frequently described as “high-value scrap,” but value is only realized when recyclers can convert them into consistently clean, high-purity copper granules. The difference between copper that merely looks valuable and copper that is truly profitable lies in understanding cable structures, choosing the right physical separation route, and optimizing each step of the process. When these elements are aligned, cable recycling becomes not just technically feasible, but commercially reliable.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry