New Center

Cable Recycling Machines Maintenance Guide for Long-Term Efficiency

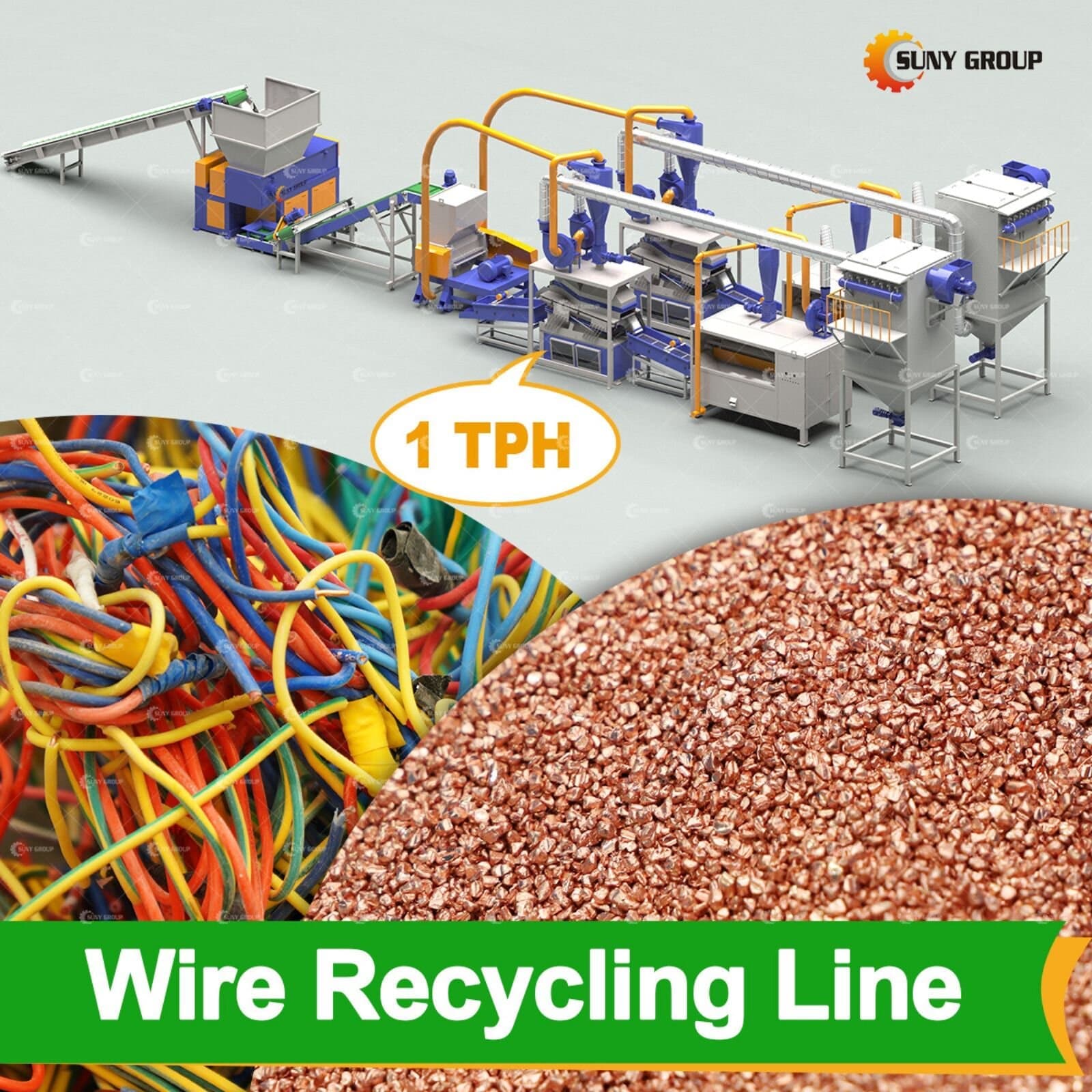

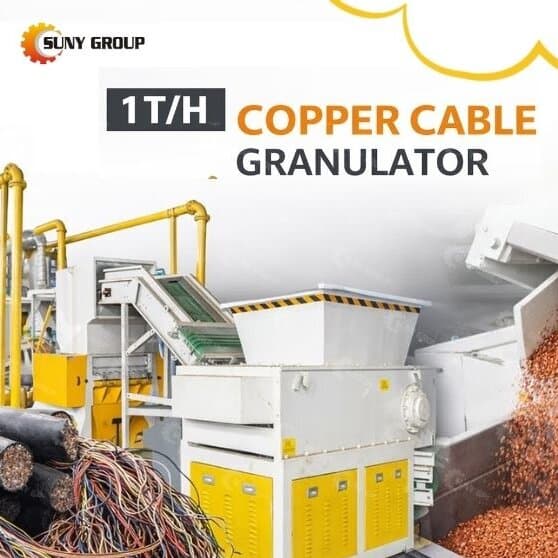

December 8, 2025As the copper cable recycling business continues to grow rapidly, buyers are increasingly focused on machine durability and long-term operating costs. Whether you are investing in a cable granulator, a wire stripping system, proper maintenance is the key to ensuring stable performance, reducing downtime, and extending service life. Modern cable recycling equipment is built with precise mechanical and electrical systems, and every component—from bearings to blades—plays a crucial role in achieving clean metal separation and high recovery rates.

Regular lubrication is one of the most important maintenance tasks. Bearings, reducers, and all moving parts must be kept well-lubricated to reduce friction and prevent premature wear. Bearing grease should be added every 1–2 days depending on workload, while reducers require gear oil added according to the level indicator. Neglecting lubrication will cause overheating, mechanical resistance, and eventual breakdowns. In addition to lubrication, maintaining clean working conditions is essential. Dust, insulation fragments, and metal particles can accumulate on motors, sensors, and electrical panels, affecting output quality and even causing electrical failures. A routine cleaning schedule—using compressed air, wiping pipelines, and removing debris from conveyors—ensures smooth, reliable operation.

Cutting tools and blades require consistent monitoring because they directly determine crushing efficiency and separation quality. After long-term use, crusher knives become dull and must be re-sharpened or replaced. Mechanical grinding is recommended to maintain the correct blade angle. When the gap between the fixed and moving blades becomes too large to meet crushing standards, knife replacement becomes necessary. Similarly, cable granulators deliver the best results when all feeding batches have uniform wire diameters; mixing thick and thin wires affects separation accuracy and increases blade wear.

Electrical systems also require attention. Motor rotation should be checked during startup, sensors must be calibrated regularly, and worn wires or loose terminals inside panels need immediate correction. Dust buildup on motor windings can cause overheating, reducing motor lifespan. Operators should also be professionally trained, understand machine structure, and follow operational manuals to avoid unnecessary wear. Before loading materials, each machine should run empty for 20–30 minutes to ensure stable rotation and proper conveyor alignment.

A well-maintained copper wire recycling machine not only increases productivity but also significantly lowers long-term operating costs. From lubrication and blade care to routine inspections and operator training, every detail directly affects machine longevity and recovery quality. With consistent maintenance, your cable recycling equipment—whether a copper granulator, stripping machine—will continue delivering high output, reduced waste, and maximum profitability for years to come.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry