New Center

Advanced Copper Wire Recycling Solutions 2025

December 9, 2025In 2025, copper remains one of the most valuable and widely recycled non-ferrous metals. Scrap copper continues to command strong market prices, with most grades trading around USD $3.3–$4.5 per pound, depending on purity and classification. This makes recycled copper an essential raw material for manufacturers, refineries, and global supply chains. Scrap copper mainly originates from two sources: new industrial scrap generated during manufacturing, and post-consumer scrap recovered from demolished buildings, retired vehicles, obsolete electronics, and aging infrastructure. Whether bare or insulated, nearly all forms of copper can be recycled without degrading its physical or chemical properties, making it one of the world’s most sustainable metals.

Copper is indispensable in electricity, construction, telecommunications, transportation, renewable energy, HVAC systems, and industrial machinery—especially copper wire, which represents the largest single application. As global electrification accelerates through EV charging infrastructure, solar farms, data centers, and power grid upgrades, the demand for recycled copper continues to rise. According to the most recent international data, approximately 30–33% of global copper demand is supplied by recycled copper, while recycled-content copper accounts for around 16.9% of world copper output. This increasing reliance on secondary copper highlights the growing need for efficient, environmentally friendly recovery technologies such as copper wire granulators.

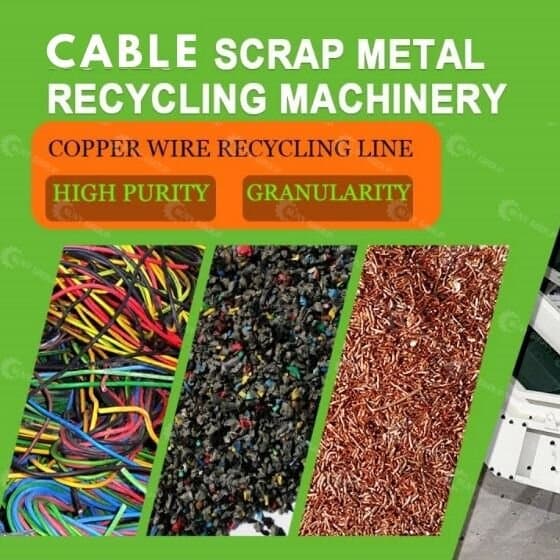

Modern copper wire recycling machines use advanced dry physical separation systems to recover copper and plastic from waste cables with exceptional efficiency. Under optimal operating conditions, these machines can achieve copper purity levels approaching 99.9%. The recovered copper granules retain nearly the same market value as high-grade refined copper. Dry-type recycling technology eliminates secondary pollution, avoids chemical treatment, and consumes only a small fraction of the energy required to mine and smelt primary copper. With environmental regulations tightening and circular-economy policies expanding worldwide, these machines have become essential equipment for copper recyclers in 2025.

Recycling copper is both economically attractive and environmentally necessary. Traditional copper mining and refining require significant fossil-fuel consumption and generate emissions such as sulfur dioxide and fine particulates. By comparison, recycling copper uses about 85% less energy than producing copper from ore and dramatically reduces carbon emissions. Recycling also reduces landfill pressure and lowers waste-management costs. Because processing scrap is far more cost-effective than mining new copper, the recycling sector enjoys stable profit margins and remains one of the fastest-growing segments of the metals industry.

A modern copper wire granulator can process communication cables, automotive wiring harnesses, household wires, and mixed scrap cables into clean copper and plastic granules. High levels of automation ensure strong productivity and stable operation for recycling plants of various scales. To maximize profitability, operators must understand copper classification. Bright copper (pure, uncoated copper) commands the highest price, followed by No. 1 heavy scrap and No. 2 copper, with each grade priced according to purity and contamination levels. Identifying copper is straightforward—it is non-magnetic, highly conductive, and recognized by its reddish-brown appearance, which turns green after oxidation.

Today, the ability to efficiently process insulated scrap cable is central to global copper recovery strategies. High-performance copper wire recycling machines improve recovery rates, enhance economic returns, and support international sustainability goals. As global demand for copper continues rising alongside electrification and renewable energy expansion, clean recycling technology will remain the most important pathway for supplying affordable, high-purity secondary copper to the world market in 2025 and beyond.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry