New Center

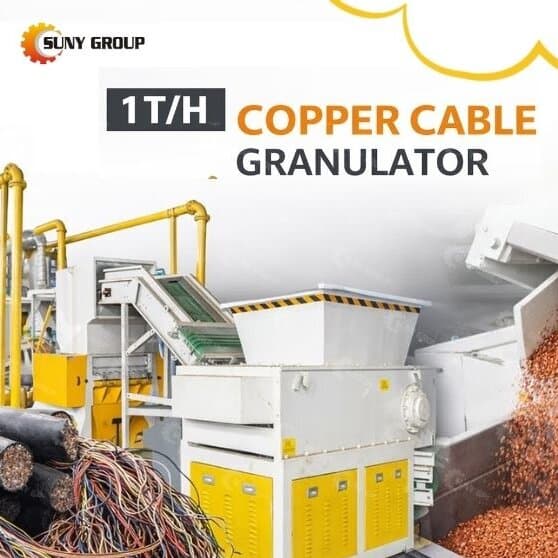

1000 kg/hr Copper Cable Granulator Process Flow Description

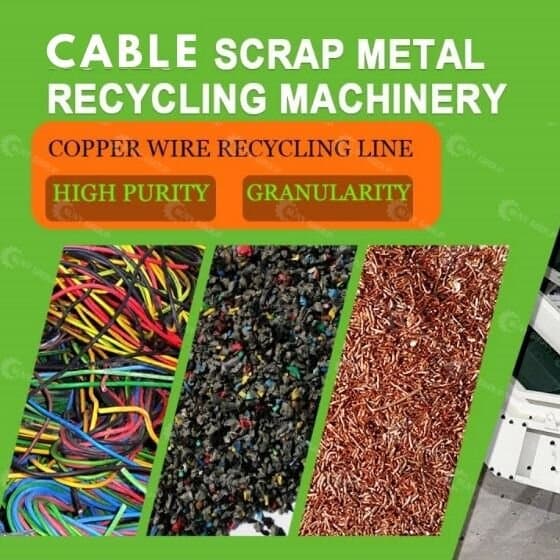

February 4, 2026The Copper Cable Granulator Line features a linear, modular layout and operates with fully dry mechanical technology to ensure stable performance and easy maintenance. Scrap cables are fed by conveyor into a single-shaft shredder for pre-shredding, then pass through a magnetic separator to remove ferrous impurities. The material is subsequently granulated to fully separate copper from insulation and conveyed by air systems to the separation section. Multi-stage air separators and vibrating screens efficiently separate light plastics from heavy copper granules, while optional electrostatic separators further increase copper purity when required. Pulse-jet dust collection systems control dust throughout the process. The line outputs clean copper granules and plastic fractions ready for sale, and the configuration can be flexibly adjusted to suit different materials, site conditions, and capacity requirements.

1000 kg/hr Copper Cable Granulator Process Flow Description (Engineering Specification – Equipment No. a–k)

a) Feeding Conveyor

The feeding conveyor is designed to provide continuous and controlled feeding of scrap copper cables into the recycling line, ensuring stable material input for downstream processing.

b) Single-Shaft Shredder

The single-shaft shredder is used to pre-shred scrap cables into uniformly sized pieces. This stage reduces material size and facilitates consistent granulation performance.

c) Belt Magnetic Separator

The belt magnetic separator is installed to remove ferrous materials from the shredded cables, preventing damage to downstream equipment and improving overall system reliability.

d) Discharge Conveyor

The discharge conveyor transfers material from the magnetic separation stage to the fine granulation stage, maintaining a steady and uninterrupted material flow.

e) Knife-Type Granulator

The knife-type granulator is designed to finely granulate the pre-shredded cables, ensuring complete liberation of copper conductors from plastic insulation.

f) Air Conveying System (×2)

The air conveying units are used to transport granulated material to the separation section in a closed system, reducing dust emission and ensuring continuous operation.

g) Air Separator (×2)

The air separators utilize controlled airflow and density differences to separate light plastic fractions from heavy copper granules, achieving primary copper–plastic separation.

h) Linear Vibrating Screen – Copper Fraction (×2)

The linear vibrating screens classify copper-rich material by particle size, directing qualified copper granules to subsequent purification stages or final discharge.

i) Linear Vibrating Screen – Plastic Fraction (×2)

The linear vibrating screens are used to screen and discharge plastic fractions separately, ensuring clean plastic output suitable for secondary recycling.

j) Single-Roller Electrostatic Separator (×2)

The single-roller electrostatic separators are applied to remove residual fine plastic particles from the copper fraction, increasing copper purity to meet high-quality output requirements.

k) Pulse-Jet Dust Collection System (×2)

Pulse-jet dust collection systems are installed at key process points to capture airborne dust generated during shredding, granulation, and separation, ensuring compliance with environmental and occupational safety standards.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com

Recent Posts

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry