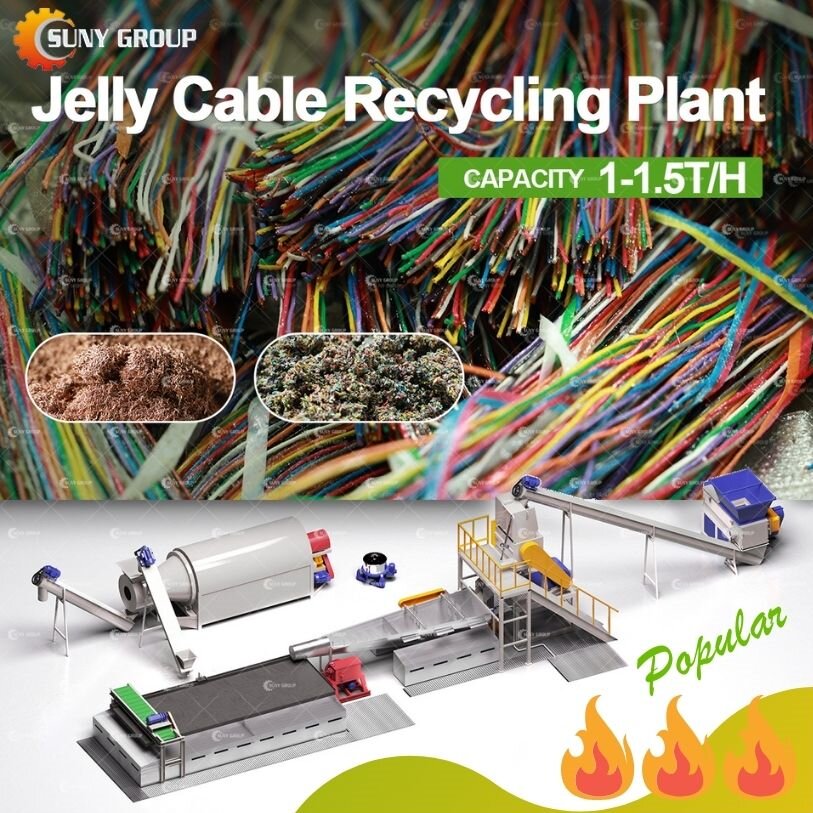

In today’s world, where sustainability meets profitability, the Cable Granulator and Separator is revolutionizing scrap recycling. This powerful machine transforms discarded cables into valuable metal, making it a game-changer for recyclers, scrapyards, and eco-conscious businesses.

The Challenge: Wasted Resources

Millions of tons of scrap cables—rich in copper and aluminum—end up in landfills each year, wasting valuable materials and harming the environment.

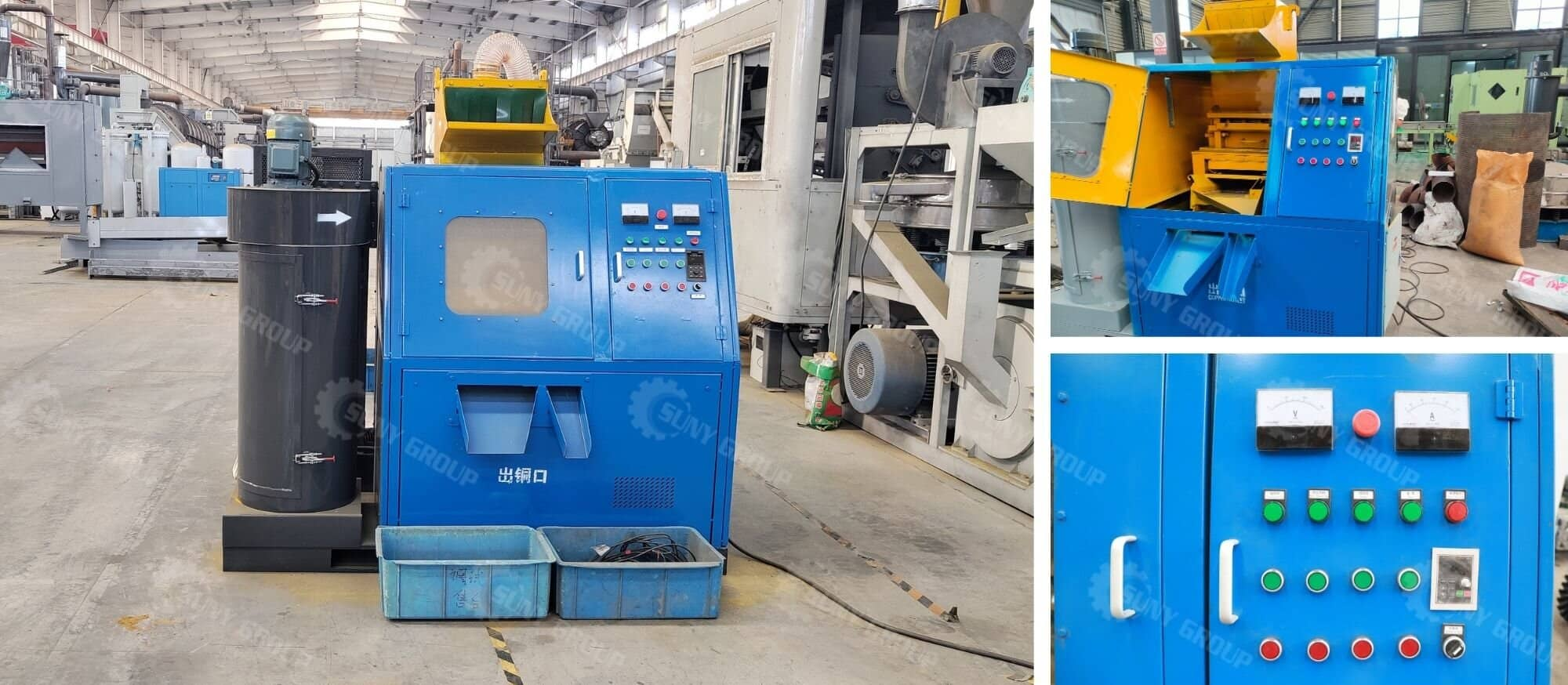

The Solution: 100kg/h Cable Granulator & Separator

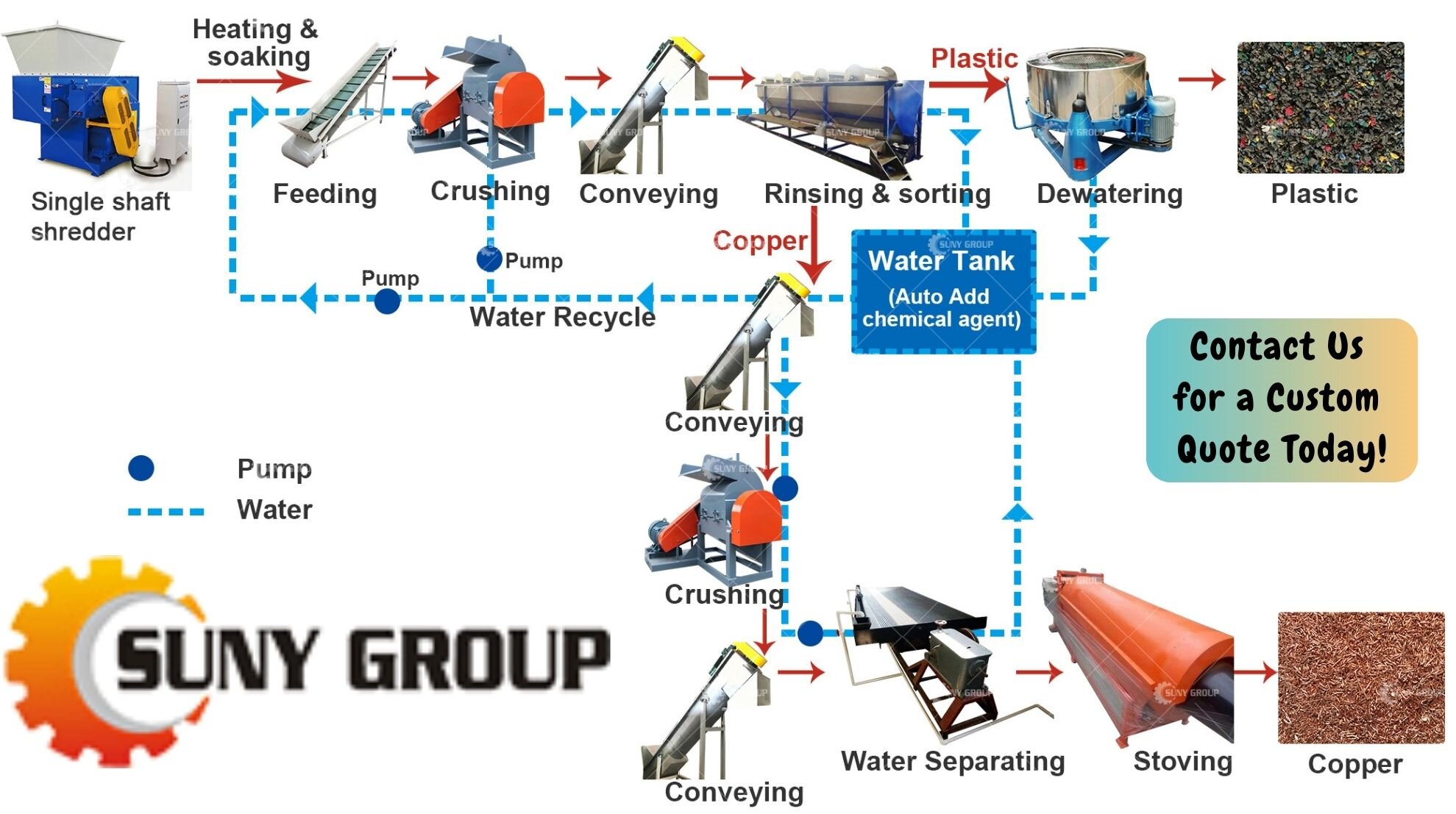

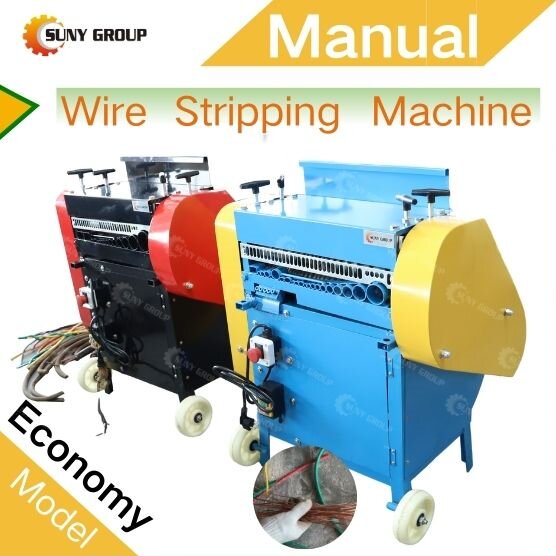

This advanced machine efficiently processes scrap cables by:

✅ Shredding cables into small pieces

✅ Crushing & Grinding to separate metal from insulation

✅ Precision Separation using air and vibration to extract pure copper or aluminum

The result? High-value metals(Copper) ready for resale and clean plastic for recycling.

Why It’s a Profit Machine

💰 Maximized Metal Recovery – Extracts nearly all valuable metal, boosting returns.

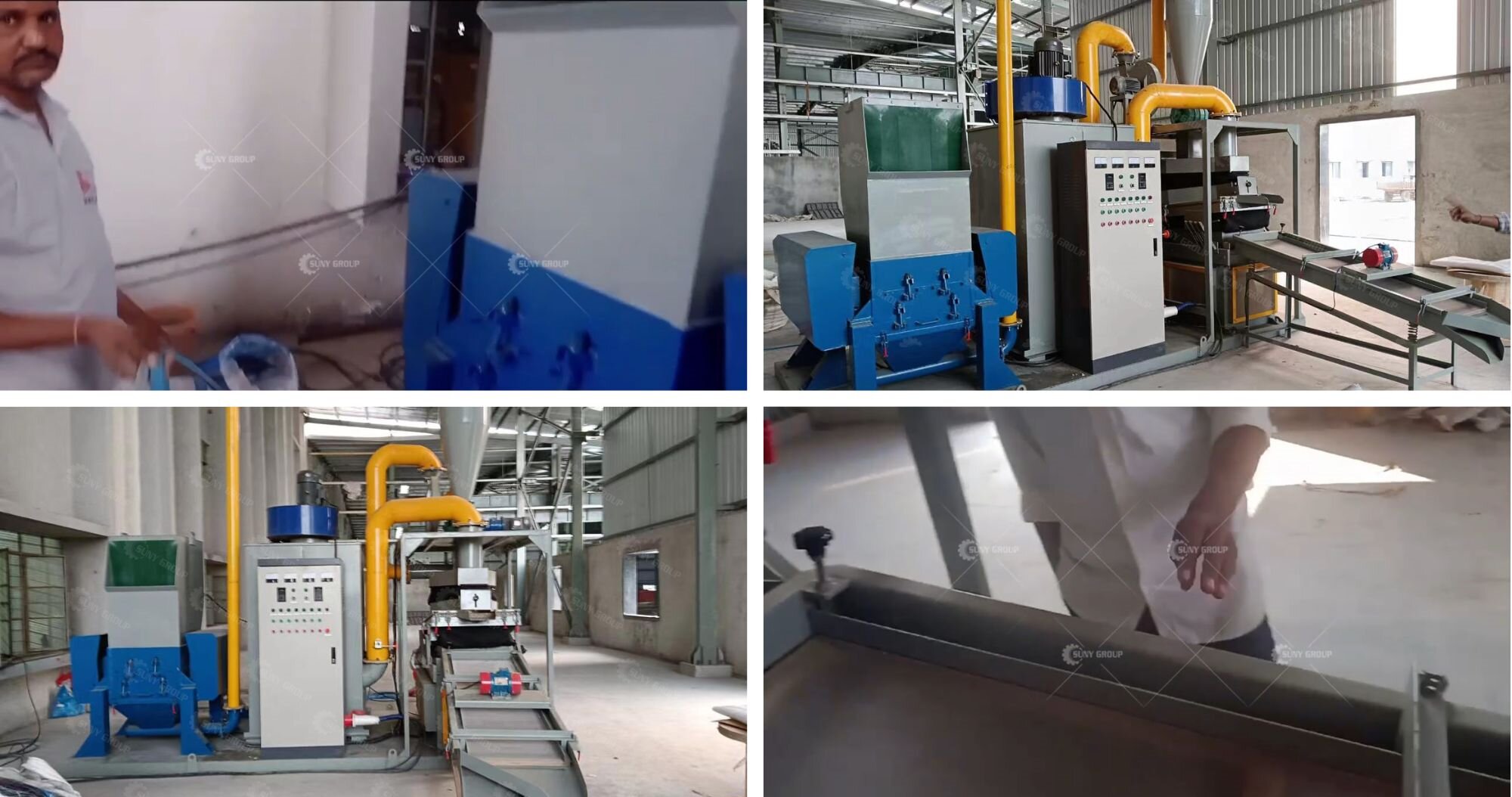

⚙️ Low Operating Costs – Automated processing reduces labor and expenses.

🌍 Eco-Friendly – Reduces landfill waste and promotes sustainability.

🔄 Versatile – Handles everything from household wires to industrial cables.

Get Started Now

Don’t let scrap cables go to waste – start turning them into pure profit today! You can contact us if you need this small cable recycling equipment, and we’ll provide training and support to help you get started quickly.

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com