Recently, our company successfully completed the production and assembly of a 300kg/h copper cable recycling machine, which will be shipped to the factory of an Indian customer. This is another successful case we have achieved in the international market, demonstrating our professional technology and efficient service in the field of machinery manufacturing.

In order to ensure that the operating data of the equipment meets the standards for factory delivery, we conducted rigorous tests after the production was completed. We carefully selected a batch of waste cables to simulate the actual working environment and comprehensively test the performance of the equipment. During the trial run, the equipment ran smoothly and all data met the standards. The most satisfying thing is that the separation rate of copper cables is as high as 99%, far exceeding the customer’s expectations. Through this test, we verified the efficiency and reliability of the equipment and ensured that customers can obtain the best separation effect in actual use.

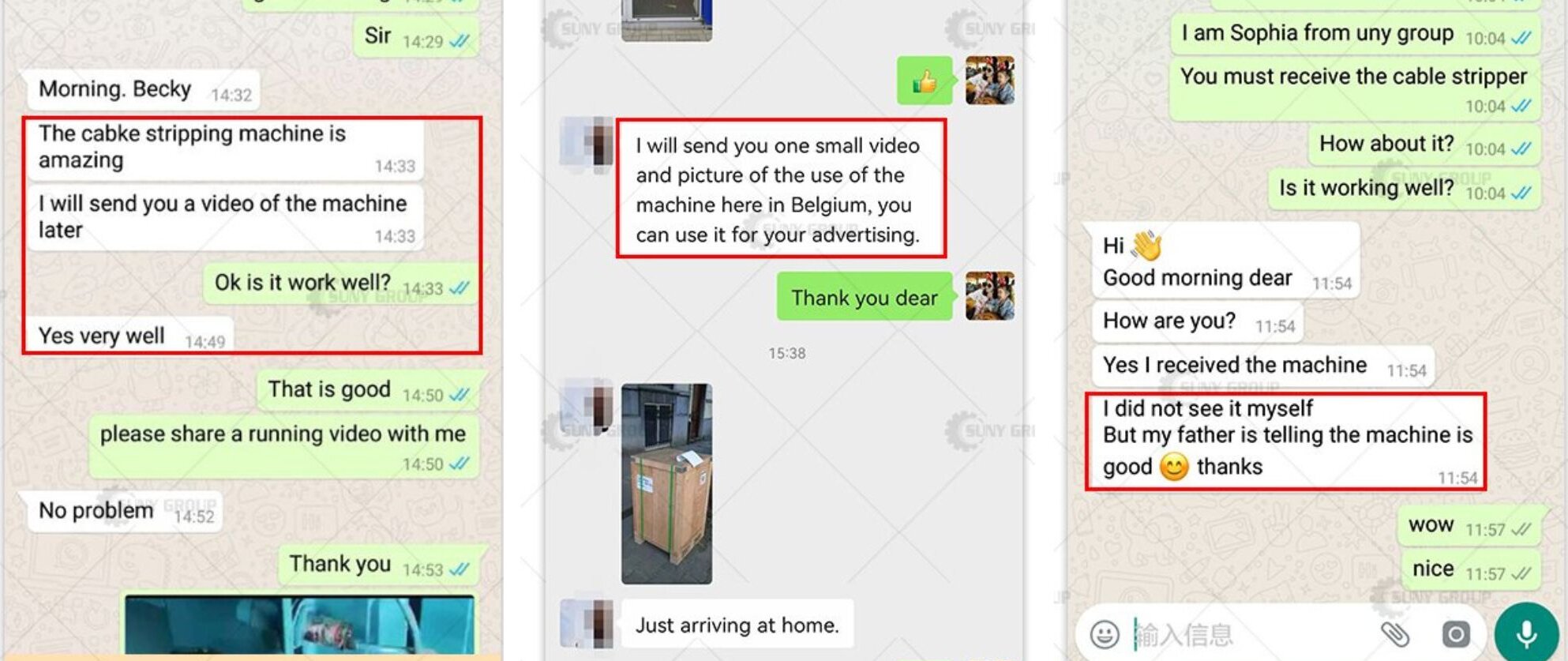

The Indian customer highly appreciated our rigorous attitude and professionalism. After learning about our test results, he was even more confident in our equipment. In order to further ensure the performance of the equipment in its factory, the customer specially mailed a batch of cable materials that they actually wanted to recycle from India. We immediately conducted a second test after receiving these materials. The results once again proved the superior performance of the equipment, the discharging results were satisfactory, and all data met the customer’s requirements. In order to make customers more assured, we retained all samples of the test discharging and provided them to a third party for inspection. In this way, we hope to provide customers with a more transparent and fair use experience and ensure that every penny spent by customers is worth it.

This cooperation with Indian customers once again proves our leading position and excellent service in the field of mechanical equipment. Through rigorous testing and multiple verifications, we not only provide customers with efficient and reliable equipment, but also win the trust and praise of customers. If you are interested in our products or have any questions, please feel free to contact us. We will serve you wholeheartedly and provide the most professional solutions.